Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Etch Pattern of Swirl Defects in Silicon

Material Name: Silicon

Record No.: 31

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: No data

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: The crystal was grown with the float-zone technique and represented the state of the art in about 1972. The

typical spiral pattern of the small etch pits lead to the name "Swirl defects". These defects were extremely

detrimental to the functioning of integrated circuits and power devices made from the wafer. It was thus of prime

importance to learn about their nature so that they could be avoided.

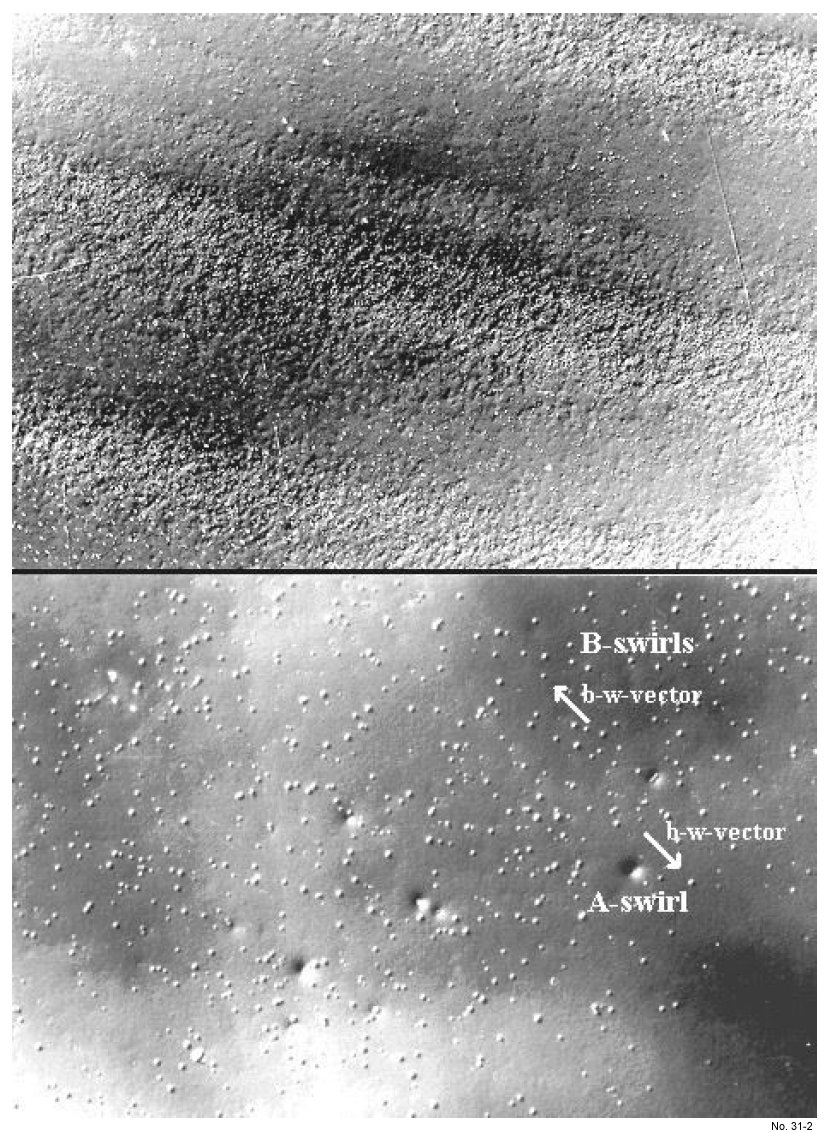

The picture 1 was taken under "dark field" conditions. The wafer is illuminated at an angle; only light that is scattered at

defects reaches the lens of the camera. Perfect areas are totally black. The defects must be due to agglomerates of

the point defects (including perhaps the major impurities O and C) that were present a high temperatures -

presumably in thermal equilibrium.

Lots of small etch pits can be seen in a striated pattern - the swirl pattern. The inner areas of the wafer may only

contain these "B-type" defects, whereas closer to the edge of the wafer, some large hillocks - the A-type" swirl

defects are contained within the B-defects. Hillocks and pits give different signs of the black-white contrast (the vector

from the black part of the contrast to the white part); this serves to distinguish between the two possibilities.

The a-type swirl defects are dislocations loops and dislocation loop clusters of interstitial type - the loops shown

before. This result was the first direct observation that showed that self interstitials play a role in Si. Etching

techniques can not provide a result like that.

In fact, it was never possible to establish the nature of the B-type defects. They might be "fore-runners of the Atype

defects - i.e. some kind of interstitial agglomerate - or small vacancy agglomerates; possibly small voids;

but nobody knows for sure.

Since present day crystals are much larger and grown with different techniques, swirl defects are now longer

seen. But other types of defects (called C- and D-defects) are present now and always first detected by optimized

preferential etching solutions. D-defects meanwhile have been identified as small voids, i.e. vacancy

agglomerates.

Reference: Website https://www.tf.uni-kiel.de/matwis/amat/elmat_en/index.html, 2020.

Figure 1: The micrograph shows a 100 mm Si wafer after preferential etching. The wafer was cut from a large as-grown crystal

and only polished before etching.

Figure 2: The etch pattern at high magnifications as seen through an optical microscope reveals two types of defects.