Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

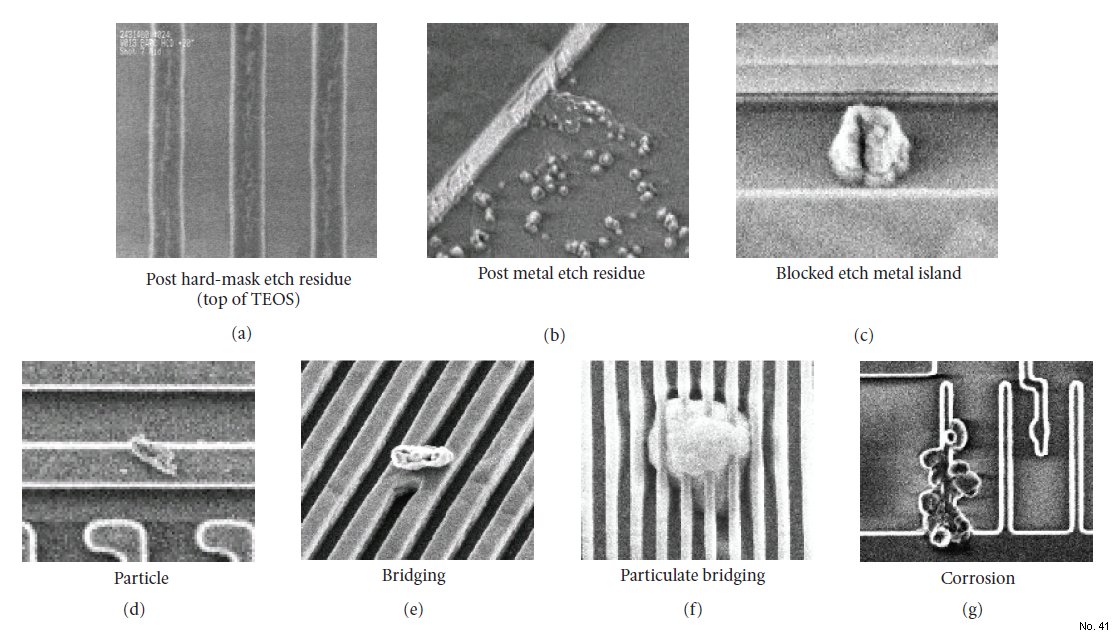

Examples of Defect Adders Within the Oxide-Masked Al Etching Process Sequence

Material Name: Aluminium

Record No.: 41

Primary Chemical Element in Material: Al

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: As illustrated in Figure 1, the defect types, referred

to as “post hard-mask etch residue,” “post metal etch

residue,” “blocked etch metal island,” “particle,” “bridging,”

“particulate bridging,” and “corrosion,” were found at the

early stage of development. Interestingly, the major adders of post hard-mask etch residue, post metal etch residue, and

blocked etchmetal island were particularly high in the oxidemasked

Al patterning but few in the conventional resistmasked

Al patterning. From the observations of scanning

electron micrographs as shown in Figure 1, these three defect

types pose a tangible and substantial yield risk due to their

subtle physical characteristics and high density on wafer.

Hence, it is important to understand the behavior of these

defect adders within the Al etching process sequence.

Reference: Hong-Ji Lee, Che-Lun Hung, Chia-Hao Leng, Nan-Tzu Lian, Ling-Wu Young,

Tahone Yang, Kuang-Chao Chen, and Chih-Yuan Lu, Etch Defect Characterization and Reduction in

Hard-Mask-Based Al Interconnect Etching, International Journal of Plasma Science and Engineering, Volume 2008, Article ID 154035, pp. 1-5.

Figure 1: Examples of defect adders within the oxide-masked Al etching process sequence.