Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Post Metal Etch Residue - Al Layer

Material Name: Aluminium

Record No.: 42

Primary Chemical Element in Material: Al

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

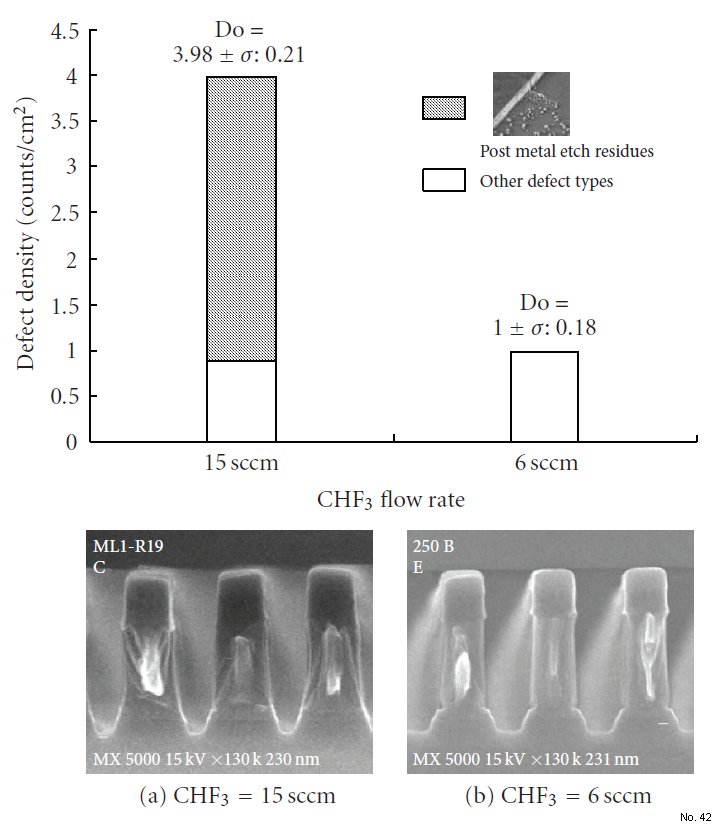

Note: After the TEOS hard mask was patterned, the remaining

metal stack was etched on Alliance 9600PTX. Figure 5(a) shows the cross-sectional SEM micrograph of Al interconnect

etched using high CHF3 (15 sccm) flow rate during

the ME step in the starting etch baseline; the Al profile was

tapered and notch-free. Subsequently, the defect inspection

in die-to-die mode revealed the defect adder density around 3.98 defects/cm2 in average, in which the major defect type

is post metal etch residue (78% of total defect adders). Upon

SEM review, the residues are found to be concentrated near

the semi-iso Al-damaged sidewall and do not appear to be

randomly distributed. From the analysis of EDS spectrum

(see Figure 6) attained from a representative residue adder,

the defect contains Al, F, Cu, Si, and Cl atoms. The data

indicate that the residues are related to the attack of the

Al (0.5% Cu) sidewall by Cl atoms, and too much CHF3

addition in the ME step could passivate the surface of Al resulting in poor capability to remove the Al-containing

residues. As expected in Figure 5(b), the extent of Al residue

was decreased with decreasing CHF3 additive gas (6 sccm) in

the ME step; the ratio of Al residue to total defect adders was

suppressed from 78% to 2.7%. The reduction of the CHF3

flow rate in the ME step can effectively improve the post

metal etch residue issue, but it will also result in less passivant

on the metal sidewall to protect the Al bottom corner from

the attack of Cl atoms. As shown in Figure 5(b), a slight

bottom notching was observed on the Al corner. Therefore,

there is a tradeoff between Al notching elimination and

residue removal.

Reference: Hong-Ji Lee, Che-Lun Hung, Chia-Hao Leng, Nan-Tzu Lian, Ling-Wu Young,

Tahone Yang, Kuang-Chao Chen, and Chih-Yuan Lu, Etch Defect Characterization and Reduction in

Hard-Mask-Based Al Interconnect Etching, International Journal of Plasma Science and Engineering, Volume 2008, Article ID 154035, pp. 1-5.

Figure 1: (a) SEM micrograph of Al profile etched using 15 sccm of

CHF3 during the ME step. The major defect type is post metal etch

residue (78% of total defect adders). (b) The ratio of post metal etch

residue to total defect adders was decreased to 2.7% at the lower

CHF3 flow of 6 sccm; however, there is a slight Al bottom notching

observed from physical profile.Defect density (Do) was expressed as

means ± standard deviation (sigma) in counts/cm2. Each etch condition

was tested on three wafers.