Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Scalloping Effect - Silicon

Material Name: Silicon

Record No.: 43

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

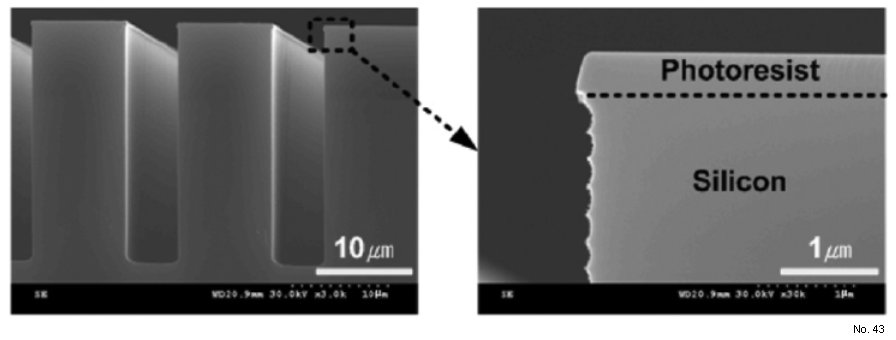

Note: The MacEtch mechanism has been established as an attractive alternative to standard

plasma-assisted etching approaches. MacEtch provides a low-cost, room-temperature, and

vacuum-condition-free substitute to reactive-ion etching (RIE) that is also devoid of the potential

for generating undesired ion-beam induced damage, irregular sidewall features, and

non-vertical etch profiles. Figure 1 shows a typical example of irregular sidewall

features (Scalloping effect) generated from deep RIE, also known as Bosch process.

Reference: SEUNG HYUN KIM, INVERSE METAL-ASSISTED CHEMICAL ETCHING OF INDIUM

PHOSPHIDE WITH SUB-20 NM SCALABILITY, MSc Thesis, University of Illinois at Urbana-Champaign, 2014, p. 2.

Figure 1: SEM images of deep trenches generated from Bosch process with a magnified view on the right.