Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

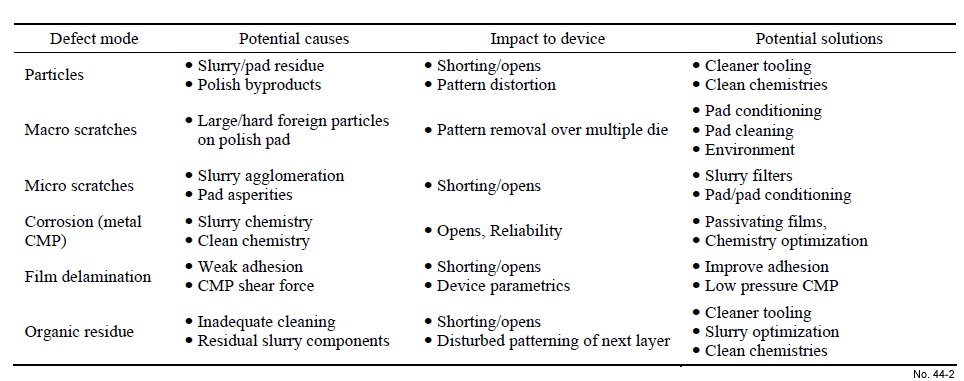

Potential Causes of CMP Defects and possible Solutions

Material Name: No data

Record No.: 44

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Polishing

Etchant Name: None

Etching Method: Polishing

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: In the manufacturing of IC chips, the wafer is polished

several times using the CMP process. CMP has been

applied for polishing various types of surfaces,

including oxides, Cu, W and others. However,

several defects induced by CMP depend on the type of surface being polished. This may be attributed to

the effects of various chemicals and abrasive particles

as well as the pressure exerted on the wafer surface. Defects typically formed during the CMP

process include organic residues, water marks,

particle adherence and impingement, corrosion

pit, and scratches. However, the removal of

organic residues and water mark formation are trivial

in oxide CMP, but other types of defects, such as

scratch formation, are critical, as they affect the yield

and reliability of the devices. Table 1 shows the

CMP process induced defects and their specific effects

on the replacement metal gate (RMG) process.

Scratches are one of the most commonly generated

defects during the CMP process. It was found that CMP

scratches could cause an initial failure as well as long

term reliability failure. The failure mechanism in

the shallow trench isolation (STI), inter-level dielectric

(ILD), and poly-Si CMP processes is very similar in

nature. Scratches cannot be detected after CMP, but are

usually identified after etching using the HF solution. The periodic arc scars generated on brittle

materials such as oxide, BPSG, and poly-Si are called

chatter mark-type scratches. Figure 1 shows

some examples of chatter mark scratches after STI

CMP. Scratch shape is influenced by the mechanical

properties of the material. A wide variety of scratches

are formed on a metal surface like Cu, which is

shown in Fig. 2.

Reference: Tae-Young KWON, Manivannan RAMACHANDRAN, Jin-Goo PARK, Scratch formation and its mechanism in chemical mechanical

planarization (CMP), Friction 1(4): 279–305 (2013).

Table 1: Potential causes of CMP defects and possible solutions.

Figure 1: Chatter mark scratches observed in STI CMP.

Figure 2: Various scratches formed in Cu CMP.