Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

µ-Scale Phenomen During CMP

Material Name: No data

Record No.: 46

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Polishing

Etchant Name: None

Etching Method: Polishing

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

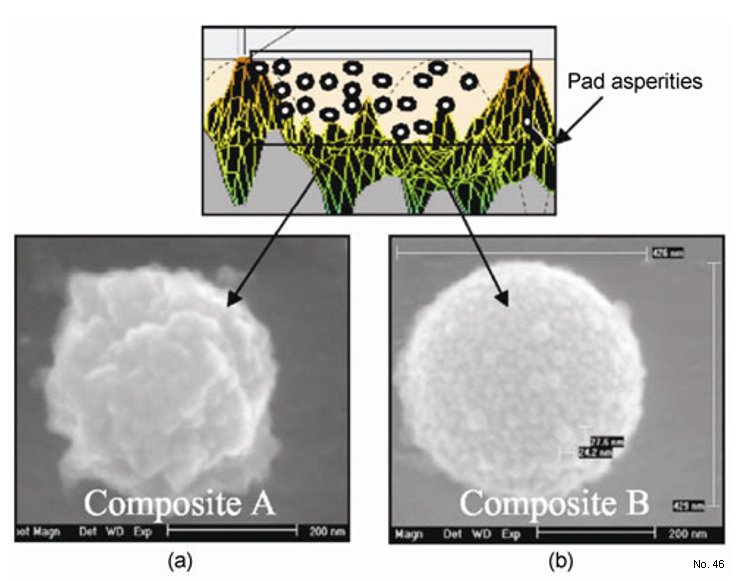

Note: A novel polymer-core silica-shell

composites were proposed by Armini et al..

Polymethyl methacrylate (PMMA)-based terpolymer

particles (diameter 350 nm) were coated with colloidal

silica particles. The coating was performed either

by creating chemical bonds using a silane coupling

agent (composite A) or by adjusting the pH to form

electrostatic attractive interactions between the core

and the shell (composite B). They focused on tuning

the mechanical properties of the polymer core by

varying its synthesis parameters. The major advantage

of the silica coating is that it can be easily modified in

terms of its surface chemistry and morphology. Also,

composite particles are aimed at improving the CMP process of soft materials due to the cushion-like effect

arising from the elastic properties of the core, which

allow the composites to easily adapt to the pad

asperities (Fig. 1).

Reference: Tae-Young KWON, Manivannan RAMACHANDRAN, Jin-Goo PARK, Scratch formation and its mechanism in chemical mechanical

planarization (CMP), Friction 1(4): 279–305 (2013).

Figure 1: Schematic diagram depicting µ-scale phenomena occurring

during CMP. SEM images of (a) composite A and (b) composite

B abrasives.