Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Scratch Level on STI Patterned Wafers

Material Name: No data

Record No.: 48

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Polishing

Etchant Name: None

Etching Method: Polishing

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: During the CMP process, the pad surface can

undergo plastic deformation and the surface becomes

smoother as the pores are filled with the pad materials. Using a glazed pad causes the removal rate to

drop significantly. Polishing pads were conditioned

with a diamond conditioner to provide consistent

performance and to prevent the glazing effect. Usually,

diamond grits used for pad conditioning are attached

to an alloy substrate using electrochemical deposition

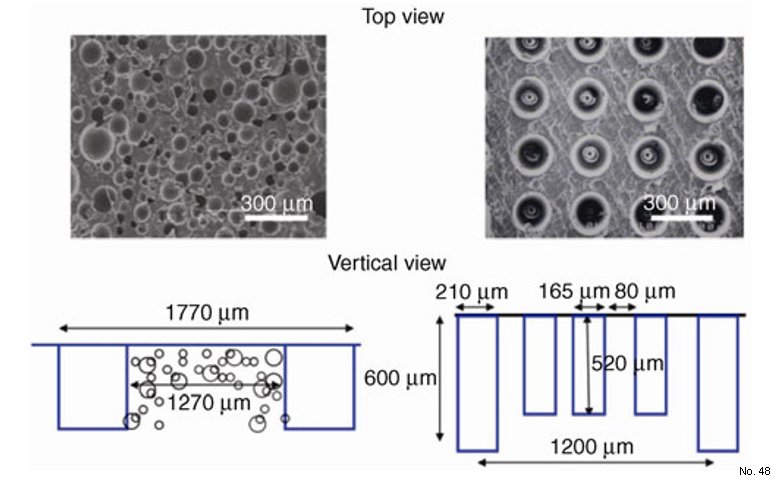

methods. Yang et al. investigated the CMP

process based on material removal rate and scratch

defects by studying the pad interaction and conditioner

effect using two types of polishing pads: a porous

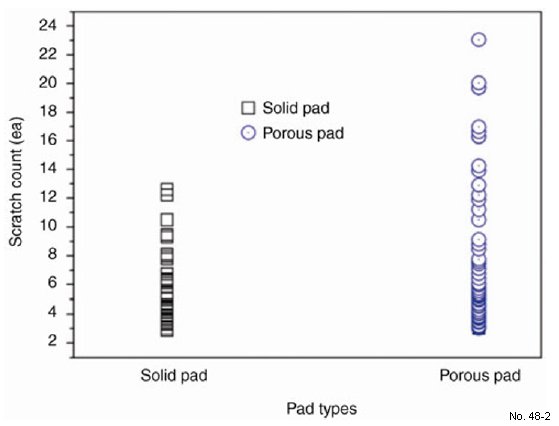

pad and a solid pad with micro holes (Fig. 24). When

a solid pad with micro holes was used with a fumed

silica slurry and a 180 µm diamond grit conditioner,

the material removal rate decreased by approximately

10% compared with the porous pad. However, the

scratch defects were reduced when compared with

the porous pad which is shown in Fig. 25. In order to

increase the removal rate obtained using a solid pad

with micro holes to a level comparable to a regular

porous pad, various diamond conditioners with

diamond size ranging from 70 to 130 µm were adopted.

Also, pad surface roughness and contact area were

analyzed to understand the removal rate and the

scratch generation. Figure 26 shows the effect of diamond size of conditioner on the removal rate and

scratch generation. It was found that the micro holes

in the pad acted as a defect source or coarse particle

reservoir to prevent micro scratching during the

process. They reported optimized results of solid

pads with micro holes using the hole depth control

procedure to reduce the defects.

As mentioned earlier, pad debris can be generated

due to tearing of the pad by the conditioner. Prasad

et al. studied the generation of pad debris and its

characterization. They reported that pad debris could

act as a main scratch source, resulting in scratches with

several size ranges with irregular shapes, mostly in

agglomerated form. It was also proposed that the

surface properties were changed by their adsorption with abrasive particles. Figure 27 shows FESEM images

of fresh pad particles and pad debris generated using

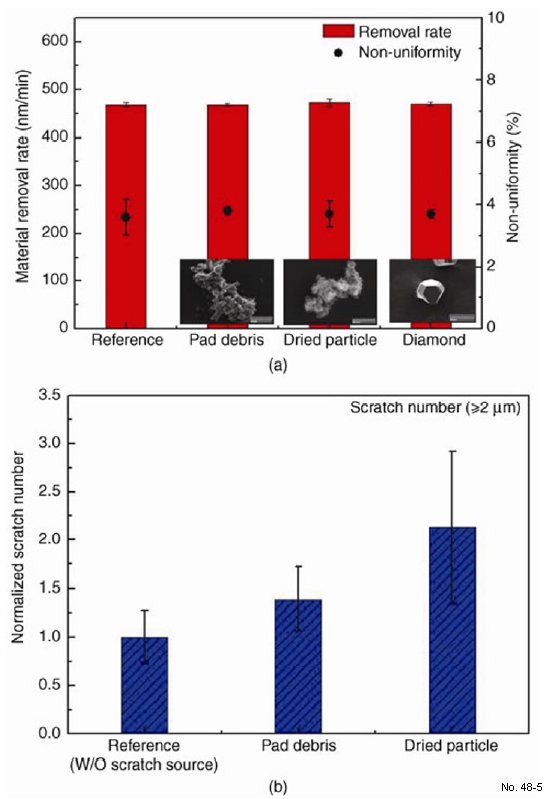

DI water and silica abrasive particles. Park’s group also investigated the scratch number using the

three different scratch source (vis., pad debris, dried

particles, and diamond particles) on scratch formation

comprehensively with their classification. Figure 28

shows the material removal rate and generated scratch

number as a function of scratch source. A small

amount of impurity in slurry did not affect the MRR.

However, scratch number was affected by the kind of

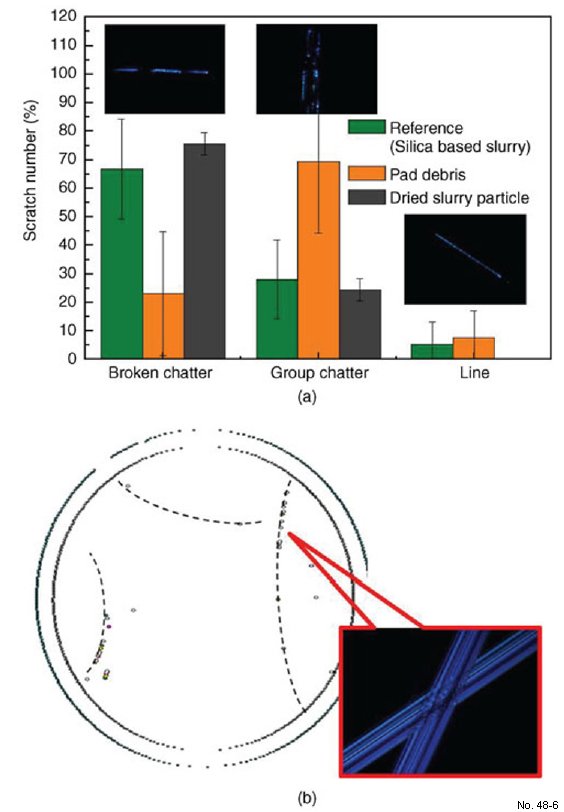

scratch sources. Figure 29 shows the distribution of

scratchess formed by adding different scratch sources

during polishing. Borken chatter type of scratches

was easily formed when dry slurry paritcles were

added but group chatter when pad debris were added.

Yang et al. measured the pad surface hardening phenomenon based on force–distance (F–D) curves.

It was found that the interaction between abrasive

particle and polyurethane pad under tribo-mechanical

action could change the pad surface hardness. Benner

et al. used a vacuum cleaner to remove the pad

debris and agglomerated large particles from the pad;

they dubbed this process the pad surface manager

(PSM). Figure 30 contains a plot of light-point defects

measured using a Tencor 6220 on polished oxide

wafers using different levels of PSM vacuum. The data

were normalized to that observed without vacuum.

As the PSM vacuum level was increased, CMP

induced wafer defects decreased. Approximately a

50% reduction in light-point defects was observed

using the PSM technique.

Reference: Tae-Young KWON, Manivannan RAMACHANDRAN, Jin-Goo PARK, Scratch formation and its mechanism in chemical mechanical

planarization (CMP), Friction 1(4): 279–305 (2013).

Figure 24: SEM micrographs (top) and schematics (bottom) of (a)

porous pads and (b) solid pads.

Figure 25: Scratch level on STI patterned wafers generated by porous

and solid pads with 180 µm diamond conditioner.

Figure 26: The effect of diamond size on (a) removal rate and (b)

scratch generation.

Figure 27: SEM image and EDX analysis of (a) fresh pad, (b) pad

debris with only DI water, and (c) pad debris with silica slurry.

Figure 28: (a) Material removal rate, non-uniformity and (b) the

variation of number of scratches formed with addition of different

scratch sources.

Figure 29: (a) Effect of addition of pad debris, dried slurry particle

and (b) diamond particles on distribution of scratch shapes formed

on oxide surface after CMP process with silica slurry.

Figure 30: A plot of the dependence of light-point defect counts,

measured with a Tencor 6220 on oxide wafers, as a function of

PSM vacuum level. A reduction of nearly 50% was observed as a

PSM vacuum.