Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Scalloping - Silicon - Dry etching

Material Name: Silicon

Record No.: 5

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: A second method, known as the Bosch Process, is a

switched-gas process that utilizes alternate steps of etching

with SF6 as the feed gas, and polymer deposition, usually

with c-C4F8 as the feed gas. The switched process is the one

more commonly used, and it requires fast acting mass-flowcontrollers

to switch between etch and deposition steps,

which occur every few seconds. An ICP etching tool is commonly

used for the process and bias power is turned on only

during the etch step and is kept low—only a few watts.

Source power during the etch step depends on the total gas

flow (to be discussed below). During the deposition step,

polymer is being formed on the horizontal surface as well as

on the sidewall. The etch step then removes the polymer

from the horizontal surface, and proceeds with etching of silicon,

while the remaining polymer on the sidewall, even

though it is being eroded, provides protection against lateral

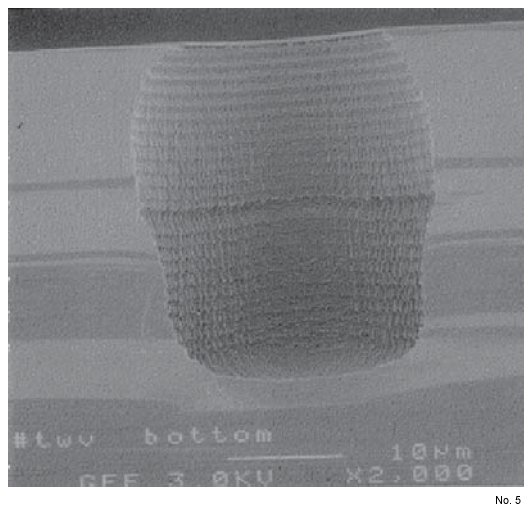

etching. The resulting sidewalls show striations (Fig. 1),

and may be an issue when smooth sidewalls are needed (e.g.,

mirror surface).

It is desirable to use etch mask and etch stop materials (if

needed) that are resistant to the fluorine plasma. SiO2,

Al2O3, and photoresist etch masks etch very slowly with

selectivities with respect to silicon of 250:1, >10,000:1, and

50:1, respectively. SiO2 and Al2O3 can also be used as an

etch stop material. Care must be used when choosing the

etch stop and etch mask material such that the material chosen

does not sputter during the etch to deposit nonvolatile

products. This will cause “grass” to form in the etched areas

due to micromasking.

Reference: Vincent M. Donnellya and Avinoam Kornblit, Plasma etching: Yesterday, today, and tomorrow, J. Vac. Sci. Technol. A 31(5), Sep/Oct 2013, pp. 050825-1 - 050825-48.

Figure 1: Scalloping associated with a switched (Bosch) process. The scallops

are the result of alternate etch and deposition steps.