Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Plastic and Brittle Fracture Scratches

Material Name: No data

Record No.: 50

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Polishing

Etchant Name: None

Etching Method: Polishing

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

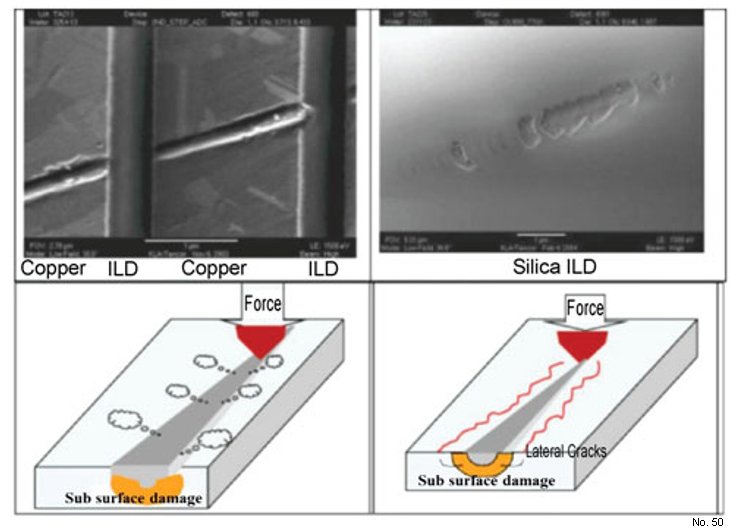

Note: Ring et al. reviewed the mechanical properties and fracture mechanics of materials in order to understand the surface damage caused during

CMP. The resulting failure was predicted by various

mechanical wear (or scratching) equations depending

upon the assumption of plastic deformation or brittle

fracture (Fig. 1). The wear rate goes from reasonably

low rates for plastic wear to rates with higher orders of

magnitude for brittle fracture.

Reference: Tae-Young KWON, Manivannan RAMACHANDRAN, Jin-Goo PARK, Scratch formation and its mechanism in chemical mechanical

planarization (CMP), Friction 1(4): 279–305 (2013).

Figure 1: Schematic of (a) plastic deformation and (b) brittle

fracture.