Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Chatter Surface Damage

Material Name: No data

Record No.: 51

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Polishing

Etchant Name: None

Etching Method: Polishing

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

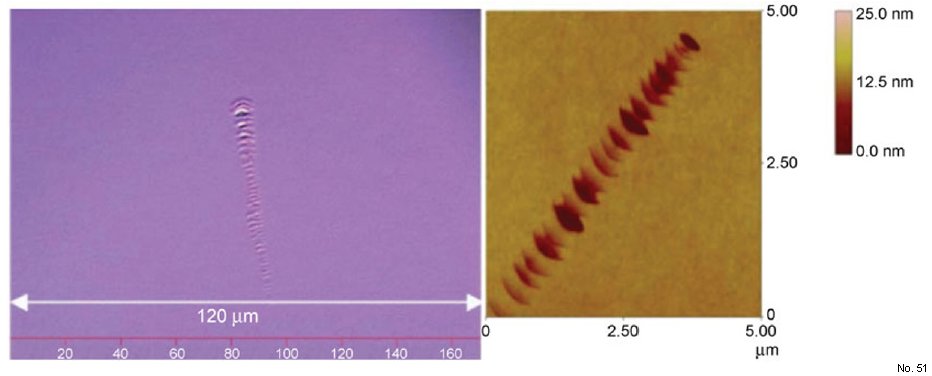

Note: Typically, chatter mark-type scratches, which have

a repetitive C-shaped crack, were generated in interlevel

dielectric (ILD) materials (Fig. 1). In this image,

the cracks are larger at one end and smaller at the other

end of the repetitive line. Furthermore, the repetitive

C-shaped surface showed damage that is tens of nm

deep with some individual cracks that were deeper

than others, in atomic force microscope (AFM) images.

Ring et al. explained this phenomenon based on

bouncing particle model. The springiness of the pad

causes the particle to bounce against the wafer surface.

Bouncing may be initiated by a particle impurity that

is sliding across the surface of the wafer. After the first

bounce, the particles have sufficient force to indent

the surface of the wafer. This force is supplied by

the elastic properties of the pad when the particle is

pushed into it and then rebounds. The frequency of

bounces can be determined by the simple physics of a

mass (the particle) on a spring (the pad).

Reference: Tae-Young KWON, Manivannan RAMACHANDRAN, Jin-Goo PARK, Scratch formation and its mechanism in chemical mechanical

planarization (CMP), Friction 1(4): 279–305 (2013).

Figure 1: Chatter surface damage showing repetitive, 40-nm-deep indentations in the wafer surface.