Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Hollows, Hillocks - Copper Wafer

Material Name: Copper

Record No.: 53

Primary Chemical Element in Material: Cu

Sample Type: Wafer

Uses: Cleaning

Etchant Name: None

Etching Method: Cleaning

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

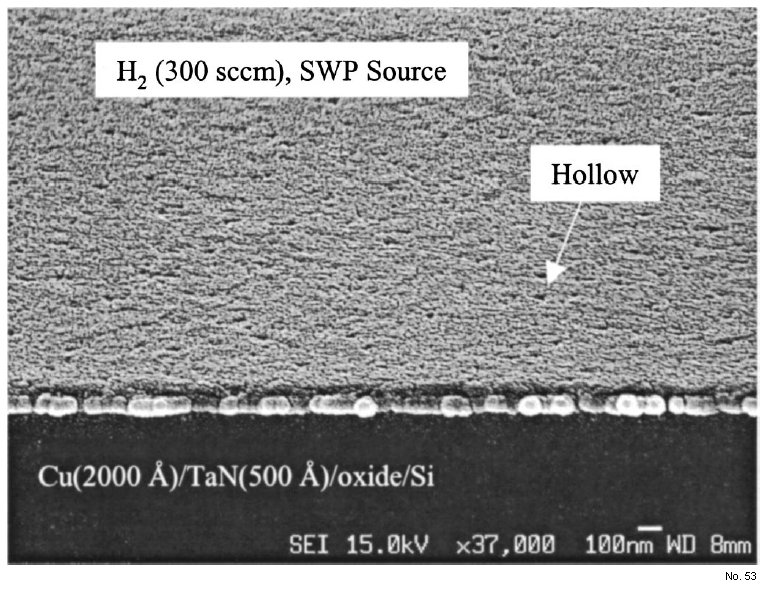

Note: To develop a more reliable plasma cleaning process, the H2 /N2

mixture plasma is suggested for Cu dual damascene process. First,

the Cu wafer was exposed to N2 plasma with the SWP source.

Compared with the control sample, the Cu surface showed no obvious

change as observed by the SEM technique. However, when the

Cu wafer was exposed to H2 plasma at 250°C, many holes formed

on the Cu surface, as shown in Fig. 5. For the control sample, native

Cu oxides were formed on the surface when the Cu wafer was

exposed to air.

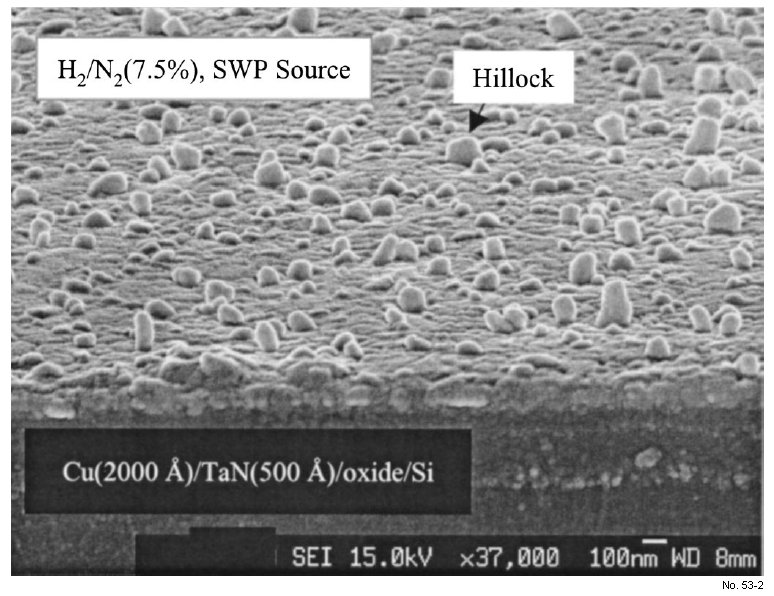

When the Cu wafer was exposed to H2 /N2 (3.75-7.5%) plasma with the SWP source at 250°C, hillocks

formed obviously on the Cu surface, as shown in Fig. 8. Seen in Fig.

9, the top view of the sample undergoing longer plasma cleaning

inspected by the SEM technique reveals the formation of hillocks

and cracks along the grain boundary. The mechanism of this hillock

formation merits further investigation.

The Cu wafer was transferred from the left load-lock chamber

(wafer chuck was set at 80°C) to the reaction chamber for 5-10 min

(the wafer chuck was set at 250-350°C), and then transferred back. In the reaction chamber, when pure

H2 or pure N2 or H2 /N2 mixed gases was used without plasma

cleaning, no obvious hillocks were formed on the Cu surface, even

when the temperature of the chuck was increased up to 350°C. Some

research has reported that metal ~example, aluminum! has a higher

coefficient of thermal expansion than silicon or silicon dioxide.

When metal films on the silicon substrate or silicon oxide are heated

(for example to 450°C sintering) during device manufacturing process,

they undergo compressive stress, which can be relieved by

hillock formation. On the contrary, when metal films on silicon substrate

or silicon oxide are cooled during the device manufacturing

process, they undergo tensile stress, which results in crack formation.

However, no obvious change on the Cu surface was observed

by the SEM technique, compared with the control sample. The experimental

results mentioned above revealed that thermal stress

from the chuck temperature is not the dominant mechanism for Cu

hillock formation. In this case, the range of chuck temperature variation

from 80 to 350°C was the largest. It is believed that the range of

temperature variation was still too small to form Cu hillocks or

cracks. According to the data mentioned above, hillocks occur on the Cu surface mainly after plasma cleaning. Therefore, it is believed

that plasma cleaning plays a dominant role in hillock formation.

Previous studies have reported that aluminum hillock growth is

enhanced during the early stage of insulator deposition. The enhanced

formation of hillocks is attributed to the increase in substrate

temperature with the application of radio frequency (rf) power.

Reference: Tsung-Kuei Kang, and Wei-Yang Chou, Avoiding Cu Hillocks during the Plasma Process, Journal of The Electrochemical Society, 151 (6) G391-G395, 2004.

Figure 5: SEM micrograph of Cu sample plasma-induced by pure H2

plasma (SWP source).

Figure 8: SEM micrograph of Cu sample plasma-induced by H2 /N2 plasma

(SWP source).

Figure 9: Top-view SEM micrograph of Cu sample plasma-induced by

H2 /N2 plasma for a long time (SWP source).