Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

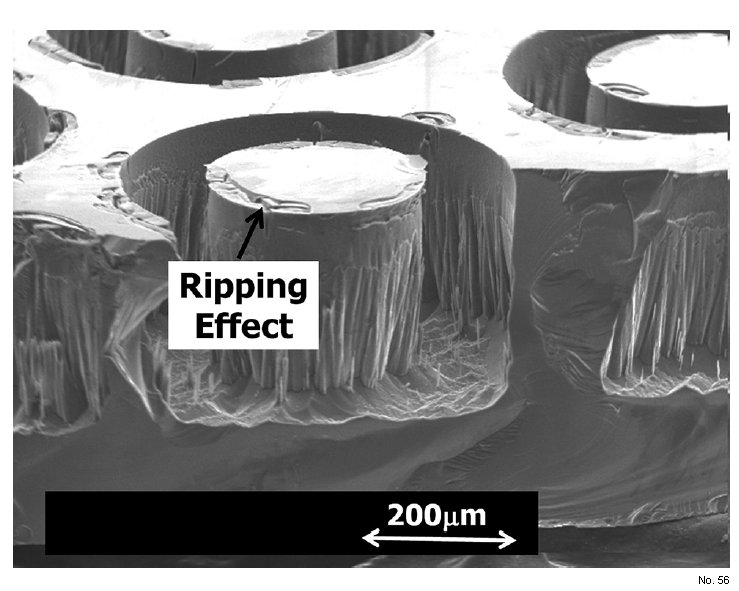

Example of an Unsuccessful Cr Lift Off

Material Name: Silicon

Record No.: 56

Primary Chemical Element in Material: Wafer

Sample Type: Layer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: There were also unsatisfactory results when using the Cr

lift-off process instead of the Cr wet etch. This was because

of a thin metal film on top of the photoresist, which came

into contact with the metal layer during deposition. This

caused a ripping effect during lift-off, as shown in Fig. 9 and

explained schematically in Fig. 10. This effect resulted in a

rough edge on the metal hard mask in Fig. 9 (the holes

shown in this figure were from an early mask design with

0.5-mm-diameter holes). These rough edges created undesirable

distortions in the hole profiles.

Reference: Ankita Verma, Joshah Jennings, Ryan D. Johnson, Marc H. Weber, and Kelvin G. Lynn, Fabrication of 3D charged particle trap using through-silicon vias etched by

deep reactive ion etching, J. Vac. Sci. Technol. B 31, 032001 (2013); doi: 10.1116/1.4799662.

Figure 9: Example of an unsuccessful Cr lift off.