Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

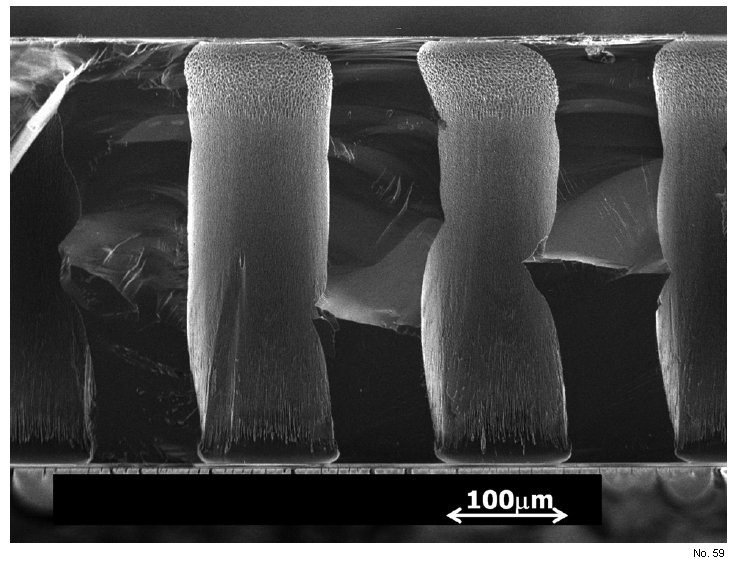

Example of Notching and Bowing Occuring in an Etched Sample

Material Name: Silicon

Record No.: 59

Primary Chemical Element in Material: Wafer

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Notching/footing: Notching and footing occur at the bottom of the etched

hole and the ions affect the oxide at the wafer back. The oxide

is a nonconducting material that accumulates negative charges

on its surface and leads to the deflection of the positive ions in

the plasma. These deflected ions start etching into the Si walls

at the bottom of the hole, as shown in Fig. 1. It may be possible

to prevent notching by using a conducting material at the

bottom of the wafer, so that the conducting material will not

accumulate a charge and deflect the ions. To test this hypothesis,

aluminum (Al) was deposited on the back side of a wafer

as an etch stop, but the Al layer, being only 0.0005 mm thick,

started breaking away faster than the oxide. Also, the thermal

conduction was better on the Al etching surface than on the

oxide, which changed the hole profile. The crystallographic

effect appeared at the bottom of the holes. If the Al backing

remained, the table temperature would need to be increased

by at least 10 .C to stop the crystallographic angles (which are

explained later in this section) forming at the hole bottom.

Reference: Ankita Verma, Joshah Jennings, Ryan D. Johnson, Marc H. Weber, and Kelvin G. Lynn, Fabrication of 3D charged particle trap using through-silicon vias etched by

deep reactive ion etching, J. Vac. Sci. Technol. B 31, 032001 (2013); doi: 10.1116/1.4799662.

Figure 1: Example of notching and bowing occuring in an etched sample.