Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Sidewall Damage - Silicon - Dry Etching

Material Name: Silicon

Record No.: 60

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

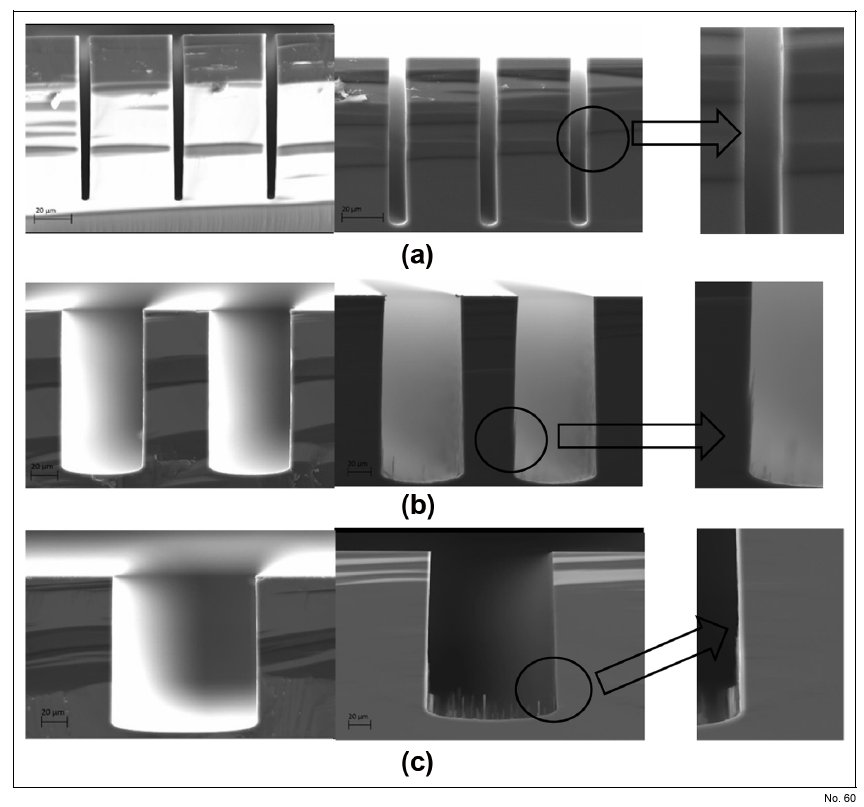

Note: In Figure 1, some obvious sidewall

damage can be seen in the trenches etched at a bias

power of 35W. As the bias power increases, the uniformity

of the ions decreases. This is caused by the fact

that some plasmas bombard the sidewall before reaching

the bottom during the etching cycle. On the upper

side of the trench’s sidewall, the polymer materials of

the deposition layer, along with some silicon, are partly

removed by the bombardment of the ions, which leads

to a rapid expansion of the trench’s width. On the

lower parts of the sidewall, the sputtered polymer materials

will redeposit onto the sidewall and form new

deposition layers, which makes it thicker than the

layers on the upper sidewalls. Several intense redeposition

functions generated by high bias power may again

shrink the width of the lower parts of the trenches,

which also facilitates sidewall damage.

Reference: Tiantong Xu, et al., Effects of deep reactive ion etching

parameters on etching rate and surface morphology in extremely deep silicon etch process with high aspect ratio, Advances in Mechanical Engineering, 2017, Vol. 9(12) 1–19, DOI: 10.1177/1687814017738152.

Figure 1: (a) SEM cross section of 6-mm-wide trenches, etched by bias power levels of 15 and 35 W, respectively. Sidewall damage

can be seen in the 35 W trenches. (b) SEM cross section of 55-mm-wide trenches, etched by bias power levels of 15 and 35 W,

respectively. Sidewall damage can be seen in the 35 W trenches. (c) SEM cross section of 110-mm-wide trenches, etched by bias

power levels of 15 and 35 W, respectively. Sidewall damage can be seen in the 35 W trenches.