Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

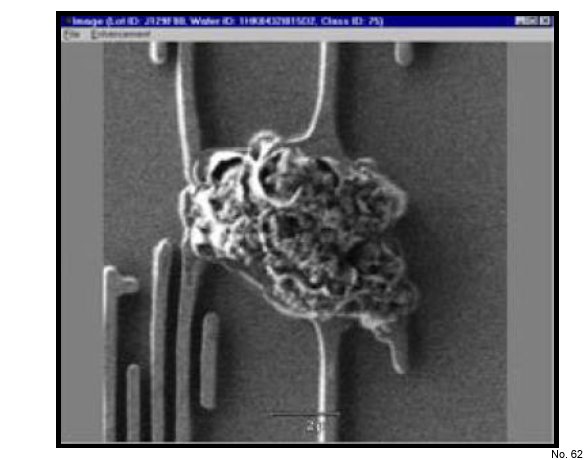

Killer Defect from Aluminum Etch Proces

Material Name: Aluminium

Record No.: 62

Primary Chemical Element in Material: Al

Sample Type: Layer

Uses: Coating

Etchant Name: None

Etching Method: Coating

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: An issue with PVD coatings is achieving crack free coatings on large parts. Typically in E beam processing the part temperature has to be elevated and the part subject to RF ion cleaning prior to deposition. The temperature uniformity and efficiency of cleaning determine the cracking tendency and adhesion of the coating. Smaller parts with simple geometries as better suited to PVD applications.

Reference: “A systematic Study and characterization of advanced Corrosion Resistance Materials and their

Applications for Plasma Etching Processes in Semiconductor Wafer Fabrication”, Hong Shih, Etch

Products Group, Lam Research Corporation, Fremont, CA www.intechopen.com/download/pdf/34479.

Figure 1: Killer defect from aluminum etch process.