Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

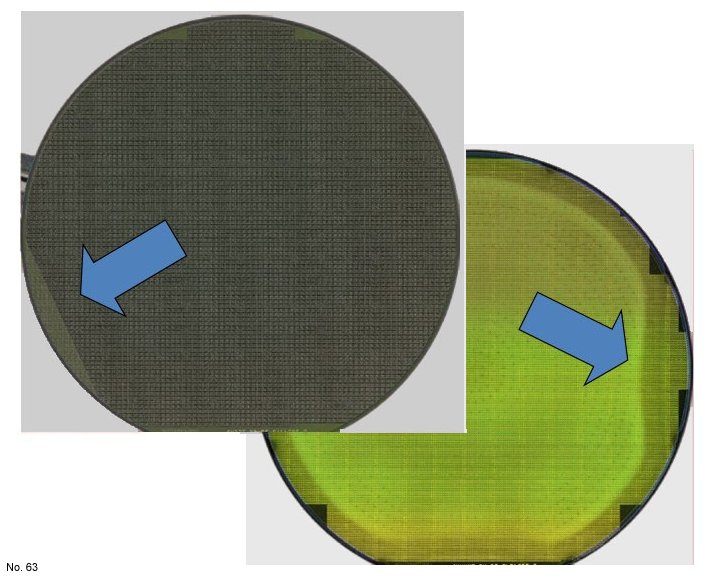

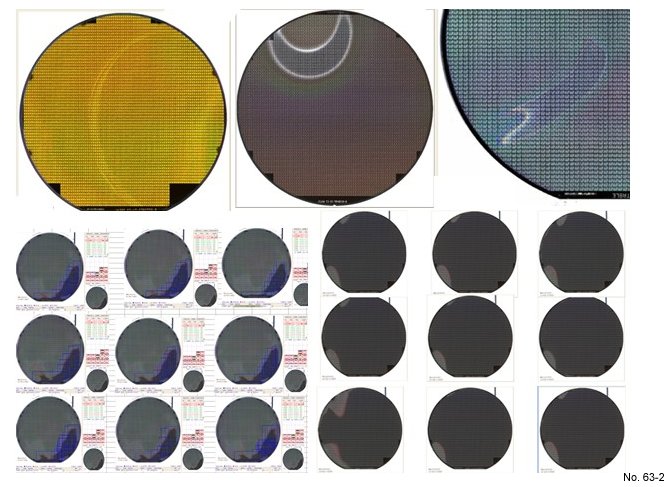

Blocked Etch Macro Defect

Material Name: Wafer

Record No.: 63

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: Blocked Etch defects are typically due to clamp-ring polymer delamination from plasma etch tools. These semiconductor wafer defects are caused by polymer build up on the etcher clamp ring that relocates laminate materials into the wafer placement area. Etch is blocked by a layer of detached polymer film. You can see in some examples above, the semiconductor wafer defect may appear to be identical and affect multiple wafers in a lot or even multiple lots.

Reference: Website https://www.microtronic.com/defect-library/blocked-etch-macro-defect/, Image and text by courtesy of Microtronic company, 2020.

Figure 1: Above is an example of a blocked etch macro defect identified by EAGLEview where the semiconductor wafers were rotated from their normal semiconductor wafer position on an etch tool. The flat edge of the clamp covered the semiconductor wafers and then these areas did not receive a complete etch.

Figure 2: Blocked etch macro defect.