Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

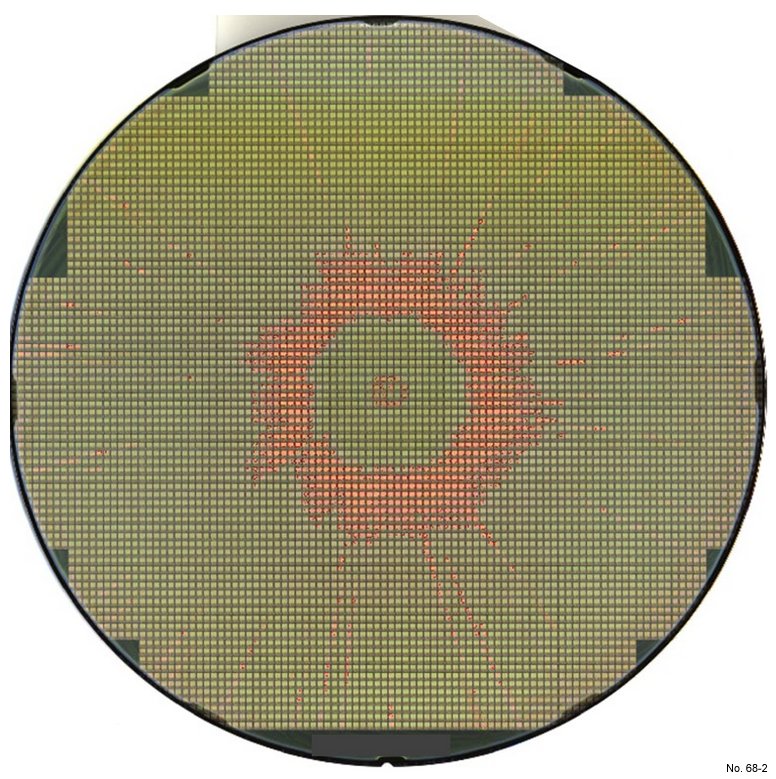

Center Spin Macro Defect

Material Name: Wafer

Record No.: 68

Primary Chemical Element in Material: No data

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Website https://www.microtronic.com/defect-library/center-spin-macro-defect/, Image and text by courtesy of Microtronic company, 2020.

Figure 1: Spin defects can occur anywhere on the wafer or throughout the entire wafer. This is an image of a spin macro defect that originated in the center of the semiconductor wafer. Spin macro defects in the center are usually due to air in the resist lines or a dirty nozzle tip that impedes the resist or causes sputtering at the start of the coat operation.

Figure 2: Some macro spin defects in the center of the semiconductor wafer can get quite large such as the example above.

Figure 3: The image above taken by EagleView is another good example of a spin defect originating in the center of the semiconductor wafer. EagleView allows you to measure the size of the defect and the percentage of the wafer impacted by the defect. In this case, the spin defect is less than 1% of the semiconductor wafer.