Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Crystalline Defects in Silicon

Material Name: Silicon

Record No.: 8

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: We have used P-type Boron doped mc-Si wafers of 10

x 10 cm2 in dimension and of about 1 Ohm x cm in electrical

resistivity. They were sawed from ingots grown by the

Heat Exchanger Method (HEM). In order to remove the

sawing process damage, we have begun by thinning and

polishing these wafers. During this step, we have used an

acidic polishing solution (known as “CP4 Etch”) made by

mixing nitric acid (HNO3), acetic acid (CH3COOH) and

hydrofluoric acid (HF) with respectively 50%, 30% and

20% concentrations. After 6 min of etching, we rinsed

thoroughly the mc-Si wafers with deionized water and

dried them under a nitrogen gun. In order to test the Secco

and Yang solutions, samples were cut from a polished mc-

Si wafer. Mainly, the etching time and the agitation mode

were varied. Before each delineation trial, the samples

were immersed in diluted HF (10%) solution for 30 seconds in order to remove the native silicon dioxide (SiO2) and then rinsed in deionized water. The Secco formulation is HF/potassium bichromate (K2Cr2O7)/H2O, obtained by mixing 2 parts of HF with 1 part of

K2Cr2O7/H2O at (0.15Moles) or (44 grams of K2Cr2O7 in

1litre of H2O). The Yang formulation is HF/chromic

acid (CrO3)/H2O, obtained by mixing 1 part of HF with 1

part of CrO3/H2O at (1.5 Moles) or (150 grams of CrO3 in

1 litre of H2O). After the Secco or Yang etching process

the samples were immediately rinsed in deionized water

and nitrogen dried. Subsequently, SEM observation and

other analysis have been performed.

Procedure (Condition): No data

Note:

The results of Yang and Secco delineation studies confirm

the revelation of crystalline defects for an immersion time

from 1 to 2 minutes, by clearly delineating dislocations,

twins, grain boundaries and dislocation lines. We observed

that dislocation pits etched with the Yang solution have

mainly triangular or quadratic forms, whereas the

dislocation pits are circular when using the Secco solution.

Figure 2 is an illustration of Secco defect delineation

process under the optimized conditions.

In order to compare the action of dislocation localization

between Secco and Yang solutions, we carried out a Secco

revelation on a sample previously revealed with Yang Etch

and vice-versa. The aim was to enable us to make a choice

between Secco and Yang Etches for the calculation of the

maximum density of defects. These tests showed that the

action of Secco is higher than Yang’s and lead us to

choose Secco for the calculation and mapping of

dislocation density. The profile of etched dislocation pits

revealed by this solution is shown on Figure 3. The

dipping time of the Secco delineation process was fixed at

5 minutes for the following defect mapping study. Such

dipping time removes 5 ìm of the dislocation zone as

shown by the SEM micrograph of Figure 3. This fine

knowledge and control of crystalline defect decoration by

“Secco Etch” on mc-Si wafers were directly applied to the

development of defect detection by the sheet resistance

variation technique.

Once the sheet resistance mapping of a polished mc-Si

wafer (10 x 10 cm2) was completed, we submitted the

wafer to a Secco etch during 5 minutes. We chose this

revelation time in order to strongly mark the defected

zones and thus obtain an appreciable variation of sheet

resistance. The mc-Si wafer revealed in this way was then

precisely placed under the 4 probes tester, and

measurement of the sheet resistance was carried out at the

initially selected positions. We plotted the mapping of

sheet resistance variation (delta R) on the 25 selected points

of the mc-Si wafer. The Figure 4 shows the layout

obtained for delta R. The next step was the superposition of

the physical image of decorated mc-Si wafer with that of

the delta R mapping. In order to accomplish this, we have

taken a digitalized photo of the whole Secco etched wafer

surface, scaled it, and finally successfully superposed it to

delta R mapping. The Figure 4 illustrates this original result.

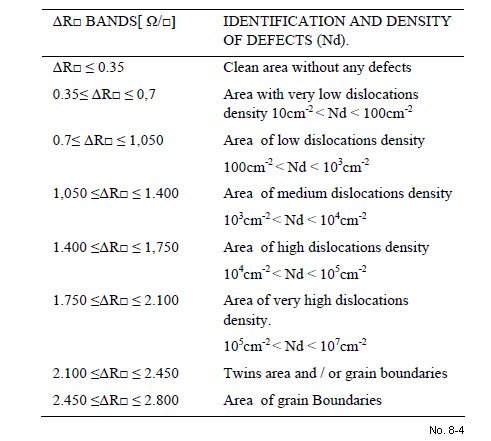

The SEM analysis of these results allowed us to make the

first classification for delta R bands according to the revealed

crystalline defect type and average dislocation density.

This classification is summarized on Table 1.

Reference: Mohamed FATHI, Ahmed CHIKOUCHE, New Method for Quality Evaluation of Mc-Si Wafers Implied in

the Fabrication of Photovoltaic Cells, Jordan Journal of Mechanical and Industrial Engineering, Volume 4, Number 1, Jan. 2010, pp. 151 - 154.

Figure 2: Secco defects delineation on mc-Si.

Figure 3: Cross section of dislocation delineated by Secco Etch for

5 minutes.

Figure 4: Superposition of the physical image of the defects area with delta R mapping.

Table 1: Classification of defects types according to sheet resistance variation bands.