Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Low Sample Temperature

Material Name: Silicon

Record No.: 95

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: No data

Reference: Burkhard E. Volland, Profile simulations of gas chopping etching

processes, PhD Thesis, Institute of Physics, University of Kassel, 2004, p. 39.

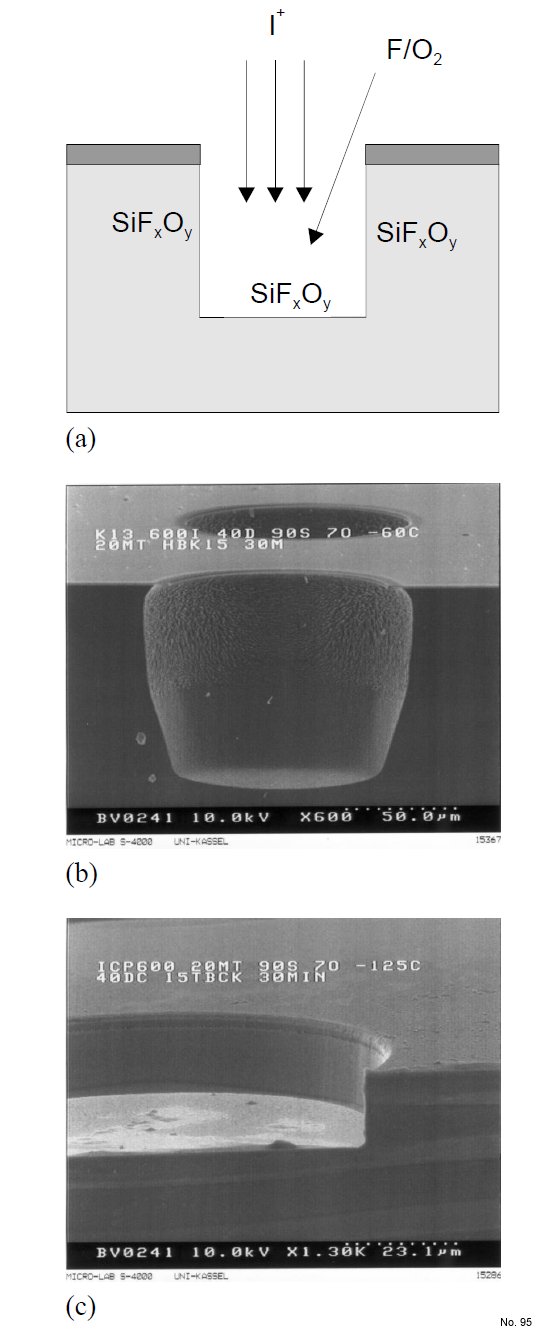

Figure 1: Anisotropy caused by

low sample temperature. Due to the

low sample temperature, the spontaneous

etching of fluorine with silicon

reduces dramatically. This effect is

enhanced by the addition of oxygen

to the process gas mixture (a). Etching

proceeds only due to ion bombardment

(ion-enhanced etching). Because

of the direct flow of ions, etching

proceeds only at the bottom, not at

the sidewalls (a). Samples have been

etched in an ICP reactor (Oxford Instruments

Plasma Technology System

100) with a 90 sccm SF6/9 sccm O2

process gas mixture, 20 mTorr operating

pressure, 60 W ICP power, 40 V dc

bias, and a helium backing of 15 Torr,

at -60 C (b) or -125 C (c). The vertical

etching rate reduces from 3 µm/min

(b) to 0.5 µm/min (c) as the sample

temperature decreases from -60 C to -

125 C, but the anisotropy of the profile

increases with decreasing sample

temperature. The sample etched at -

60 C (b) still suffers considerable lateral

etching due to the spontaneous

etching reaction of fluorine with silicon,

which vanishes at a sample temperature

of -125 C (c).