Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

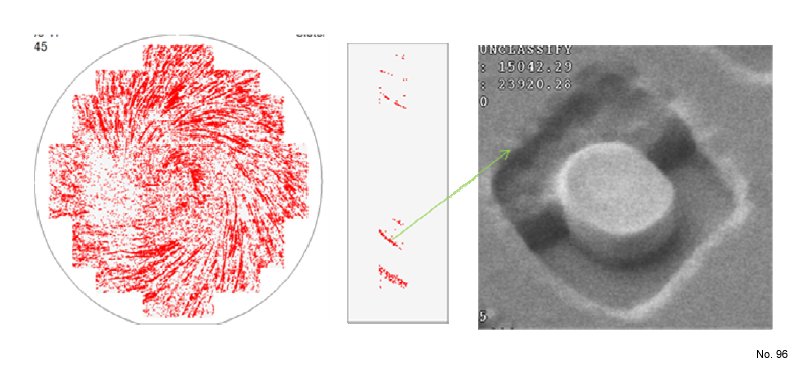

Tornado Shape After Poly-Si Wet Etching

Material Name: Silicon

Record No.: 96

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Wet etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: The reason there are Si residues is largely divided into

two categories. One is low wettability by hydrophobic Si

surface and the other one is local residues due to insoluble

H2 Bubbles that are generated during a wet etching.

At First, as shown in Figure 1, The shape of the defect

inspection map appears like a tornado that is generated by

a poor wetting, the cause of this occurrence is as follows.

Before Si etching, a pre-treatment of Fluorine series is

needed to remove native oxide. As a result, Poly-si is

significantly changed to more hydrophobic. In this state,

Alkali solutions cannot be used fully when wetting on the

wafer’s surface, and it makes tornado shaped defects in

the single type equipment. This problem can be solved

using a hydrophilic surface treatment(SC1) between

fluorine pretreatment and poly-si wet etching. This can be

demonstrated via the contact angle measurement, surface

tension of the solution is dramatically reduced by SC1

treatment. Additionally, we have learned that the

solutions having longer carbon chains have better

wettability than ammonia and small amounts of IPA with

a low surface tension added for improving wettability.

Reference: Kihyung Ko, et al., A study on the removal method of Si residue

during Si Wet Etch, Abstract #2102, 224th ECS Meeting, 2013 The Electrochemical Society, pp. 1.

Figure 1: Defect inspection map of tornado shape after

poly-si wet etching & SEM image of poly residue.