Alphabetical Index

Browse by Elements

Keyword Search

Dry Etchants

Dry and Wet Etchants

Wet Etchants

Bulk Etchants

Layer Etchants

Nano Etchants

Single Crystal Etchants

Thin Film Etchants

Thin Foil Etchants

Wafer Etchants

Al Etchants

Cd Etchants

Ga Etchants

Ge Etchants

In Etchants

New Etchants

Other Etchants

Si Etchants

Zn Etchants

Help

Home

Overlay Shift

Material Name: Silicon

Record No.: 99

Primary Chemical Element in Material: Si

Sample Type: Wafer

Uses: Etching

Etchant Name: None

Etching Method: Dry etching

Etchant (Electrolyte) Composition: No data

Procedure (Condition): No data

Note: For wafer-edge detractors, electrical

failure analysis can provide only limited

infor mation due to super position

of process issues from more layers

compared to wafer center. Extensive

rever se eng ineer ing is required,

especially if process issues or defects are

non-detectable inline. Additional delays

are caused if analysis has to be carried out in serial mode, in a similar fashion

to archaeolog ical digs uncover ing

the buried achievements of ancient

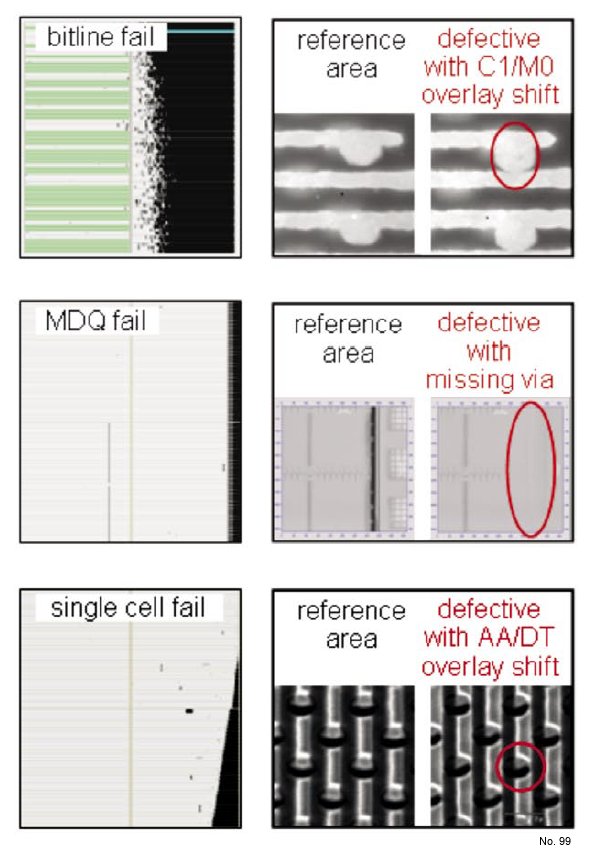

civilizations layer by layer. Figure 1

shows an example of debugging of

multiple process issues at an edge die.

Initially, only the cluster bitline fail

was observed electrically; physical failure

analysis indicated that it was due to a

local contact-to-bitline (C1-M0) overlay

shift. Within the affected die no overlay

shift was present towards wafer center.

Statistical analysis confirmed a baseline

issue for the given die which, once

fixed by appropriate overlay correction,

showed failures in master data lines

(MDQ) in the electrical fail signature.

Physical failure analysis revealed that the

observed MDQ fail was associated with

back-end-of-line metallization contact

(C2) opens. The defects were optically

non-visible by inline defect inspection.

Hence, a voltage contrast-based e-

Beam defect inspection was developed

for inline monitoring, while the issue

was addressed using blading adjustment

for the extreme edge shot. Finally,

single cell fails were detected, caused by

a localized active-area to deep-trench

capacitor (AA-DT) overlay shift at the

extreme edge of the affected die. The

cause of these fails could be attributed

to shifted DTs due to plasma distortion

dur ing hard-mask open process.

Eventually, the process uniformity could

be further optimized by a redesign of the etch tool. Learning cycles could be

further reduced by use of the Automated

Process Inspection (API) feature of

the SEM review tool. A specifically

designed API recipe provided inline

information on AA/DT overlay shift

right after AA etch in this case, which

negated the need for waiting for the

electrical test to verify the process fix.

Reference: Oguz Yavas, Ernst Richter, Christian Kluthe & Markus Sickmoeller, Wafer-edge yield engineering in

leading-edge DRAM manufacturing, Semiconductor Fabtech -39th Edition, www.fabtech.org, 2009, pp. 1-5.

Figure 1: Electrical fail signatures (left) and SEM images (right) of defects for a failing

wafer-edge die.