Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Multiphase inclusions in a Ce containing steel

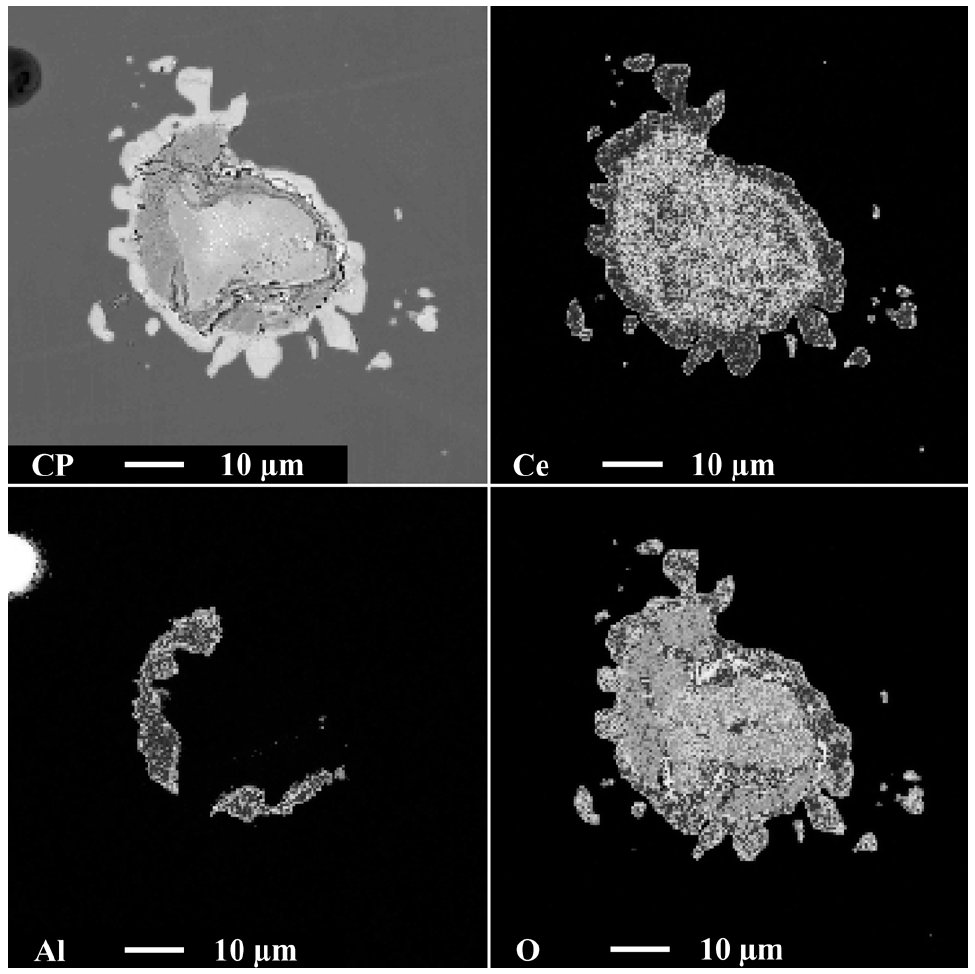

Figure 1: Microprobe X-ray mapping of a multiphase inclusions in a Ce containing steel. Scale bars: 10 µm.

Inclusion name: CeO2, CeAlO3

Record No.: 1044

Inclusion formula: CeO2, CeAlO3

Inclusion type (Macro/Micro/Nano): Macro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Oxide

Inclusion composition in weight %: No databr> Sample: Strømhard steel. This is a modified Hadfield steel produced by Scana Steel Stavanger.

Steel composition in weight %: 1.3% C, 0.3% Si, 18% Mn, 0.004% S and 0.005% O.

Note: A fine-grained microstructure yields the optimum combination of strength and toughness of steel. Moreover refinement of the as-cast structure can reduce the tendency for hot-cracking during forging and rolling. This paper describes how small inclusions can be used to control the microstructure of steels. These small inclusions (dispersoids) are oxides, sulfides, nitrides and carbides which are in the 1 mm size range and capable of promoting grain refinement during solidification by a process of epitaxial nucleation or in the solid state through intragranular nucleation of ferrite. Such particles are sufficiently small to be harmless from a toughness point of view, but at the same time large enough to act as potent nucleation sites during phase transformation. The dispersoids can either be created by balanced additions of strong oxide and sulfide forming elements to an impure steel melt or be added directly into the liquid steel through a specially designed master alloy containing the nucleating particles. In both cases it is possible to manipulate the steel microstructure in a positive direction, but the latter method, involving the use of a master alloy, has probably a wider industrial application.

Steel with Ce additions contain Ce-oxides and Ce–Al-oxides. The inclusions have been analyzed by quantitative WDS measurements. On basis of the ratio between Ce, Al and O in these inclusions, it is assumed that these are CeO2 and CeAlO3 respectively. Some larger inclusions consist of more than one phase. An X-ray mapping of such a multiphase inclusion in a Ce added steel is shown in top Fig. 1. The mapping shows that the core contains Ce-oxide while the surface phase is a mixture of Ce and Al oxide, presumable CeAlO3.

Reference: Not shown in this demo version.