Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Spinel inclusions in type 304 stainless steel

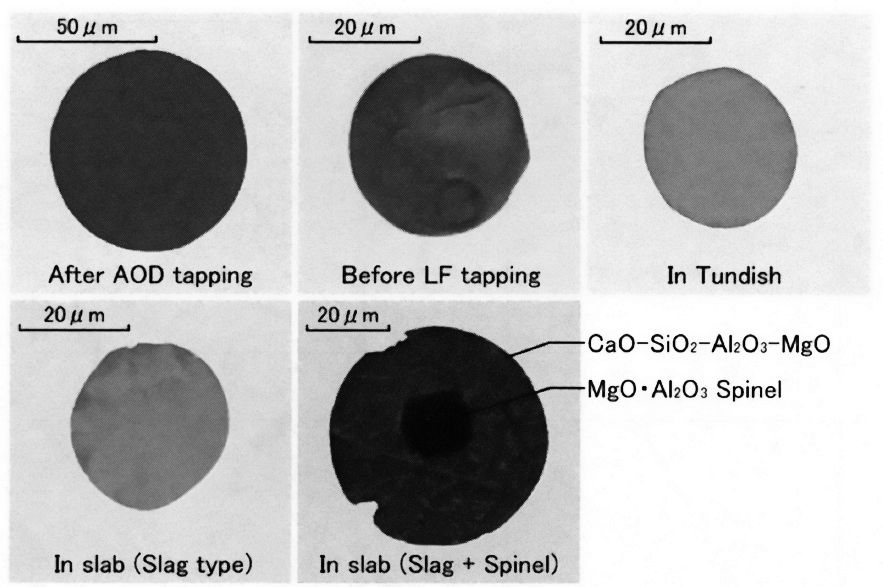

Figure 1: Representative morphology of the inclusions in molten steel and slab. Scale bars: 50, 20 µm.

Inclusion name: Spinel inclusion

Record No.: 1618

Inclusion formula: MgO x Al2O3

Inclusion type (Macro/Micro/Nano): Macro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Oxide

Inclusion composition in weight %: Representative composition of inclsion in type 304 SS slab: 39% CaO, 38% SiO2, 12% Al2O3, 8.0% MgO, 0.3% Cr2O3, 1.5% MnO.

Sample: Type 304 stainless steel

Composition in weight %: Steel type 304 SS: 0.060% C, 0.6% Si, 1.0% Mn, 8.1% Ni, 18.2% Cr, 0.0006% Al. AOD slag: 45% CaO, 29% SiO2, 1.8% Al2O3, 8.0% MgO, 0.6% Cr2O3, 10% CaF2.

Note: The inclusion of the spinel, MgO x AlO3 in type 304 stainless steel slab causes defect of surface, deterioration of mechanical property and so on, Thus, it is required to reduce the spinel inclusion. In this study, inclusions in molten type 304 stainless steel at each successive reactor, which were AOD, LF and tundish, were investigated in order to control the formation of the spinel in type 304 stainless steel slab. The formation of the spinel inclusions in the slab was discussed from the viewpoint of the effect of slag composition.

The Al2O3 content in inclusion increased in the course of production process from AOD to slab. Moreover, the Al2O3 content in inclusion in the slab increased with the increase of Al2O3 content in slag and %CaO/%SiO2 ratio in slag. The following formation mechanism of inclusion is proposed based on these results. The origin of inclusion is formed by incorporation between the suspended AOD slag in molten steel and the deoxidation products that are SiO2 and Al2O3. When temperature of molten steel falls, the original inclusion works as a nucleation site, namely, Al2O3 as a secondary deoxidation product precipitates at the original inclusion. Accordingly, the Al2O3 content in the inclusion increases. Based on the formation mechanism of inclusion, the semi-empirical model was constructed. This model revealed that reduction of Al2O3 content in slag and %CaO/%SiO2 ratio of slag was effective for eliminating the formation of harmful spinel inclusion.

Reference: Not shown in this demo version.