Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Type 7 inclusion in steel with 0.38C-5.29Cr-0.94V

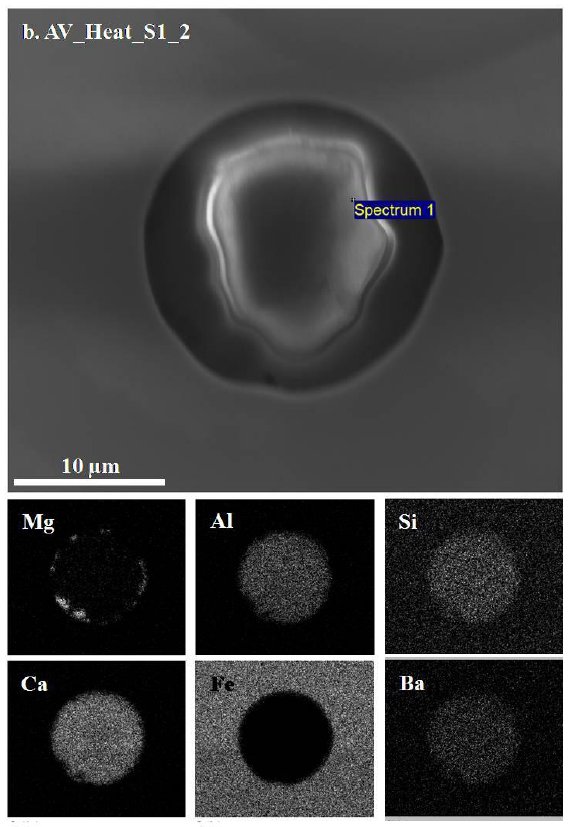

Figure 1: Type 7 inclusion, SEM, scale bar: 10 µm and X-ray maps for Mg, Al, Si, Ca, Fe and Ba.

Inclusion name: Oxide inclusion

Record No.: 466

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): Micro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Oxide

Inclusion composition in weight %: No data

Sample: Steel

Steel composition in weight %: 0.38% C, 1.06% Si, 0.43% Mn, 0.019% P, 0.0006% S, 5.29% Cr, 0.13% Ni, 0.048% Co, 0.94% V, 0.011% Al, 0.007% N, 0.0001% B, 0.0004% Ca, 0.00028% O. Slag composition: Before vacuum treatment: 10.3% MgO, 23.7% Al2O3, 13.8% SiO2, 50.1% CaO. After vacuum treatment: 10.4% MgO, 27.1% Al2O3, 12.1% SiO2, 47.1% CaO.

Note: Similarly, the micrographs of a BaO containing inclusion (also Type 7) found in the second heat of the first series (Heat_S1_2) are presented in Fig. 1. While the BaO content is lower than the inclusion No. 464, its presence in the inclusion is evidently seen or the composition ranges of inclusions found at various stages, please clik this link.

Note 2: The tracer experiments were conducted in the full scale ladle. BaCO3 was employed as the raw material of the tracer. At steelmaking temperature, the barium carbonate would decompose immediately into BaO and CO2.

Reference: Not shown in this demo version.