Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Fractures of wheel steel with nonmetallic inclusions

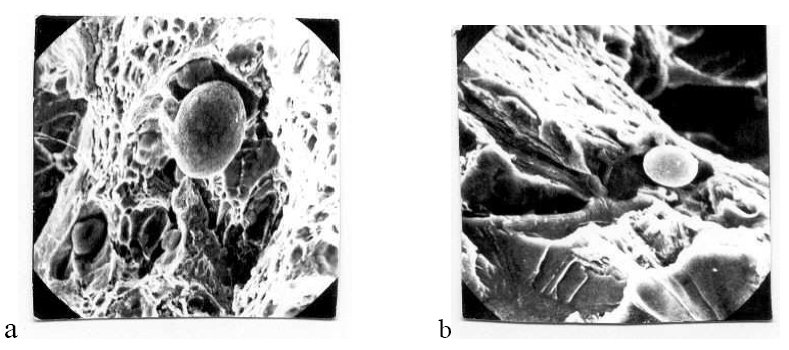

Figure 1: Fractures of wheel steel with nonmetallic inclusions, SEM, Mag. 2000 X.

Inclusion name: Inclusion

Record No.: 855

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): No data

Inclusion type (Exogenous/Indigenous): No data

Inclusion classification: No data

Inclusion composition in weight %: No data

Sample: Wheel steel

Steel composition in weight %: No data

Note: It is well known that formation of defects of many types during railway wheels service somehow or other is connected to nonmetallic inclusions in wheel steel. Microbreakes connected with nonmetallic inclusions have different origin. The first one is “deformational”, the second is “thermal” and the third is “hydrogenous”. The objective of this work is the study of nature of microbreaking in wheel steel relative to nonmetallics. Mechanisms of microbreaking of all types near different nonmetallics had been investigated and their influence on safety threshold of railway wheels had been analyzed herein.

Microbreaks near inclusions have three stages of development: nucleation, growth and integrating in mainline crack. Leading role of nonmetallic inclusions in developing of breaking is clearly shown from investigation of fractures surfaces (Fig. 1).

In such a way, nonmetallic inclusion and matrix represent the system of stressed (inclusion) and plastic layers (matrix) shared by interface. Zones of nonlinear collective strongly excited states that generate different deformational defects occur due to concentration of deformational, contact and thermal stresses near inclusion at adjacent areas of matrix. Plastic deformation near inclusions is generated as a result of max concentrations of stresses at these areas as a local kinetic structural transformation and extends into grain by means of defects movement. Elementary action of plastic deformation considered as relaxing waving process going with local stress drop. Mechanism and nature of deformation depend on deformation conditions. Deformation localization near inclusions is observe at all stages of its development. Inclusions accumulate defects becoming the sources of longdistance stress fields which are connected with local bend of lattice due to incompatibility of deformation. Nonmetallic inclusions in steel constitutes a set of stresses concentrators which magnitude and way of relaxation depend on type and size of inclusion, thermal-speed and baromechanic conditions of deformation and correlation between physicochemical properties of inclusion and matrix. Relaxation of deformational stresses near inclusions goes with localization of dissipative structures witnessing processes of self-organization in system inclusion-matrix. For deformation of microbreaks near inclusions (as one of the way of stresses relaxation) it is necessary to generate deformation waves which length is comparable with inclusion size. Influence of nonmetallics on steel fracture development is varying along with temperature and deformation level, yet level of inclusion risk for different mechanisms of steel fracture is distinct.

Additional links: Not shown in this demo version.

Reference: Not shown in this demo version.