Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Hydrogenous cracks near sulfides in wheel steel

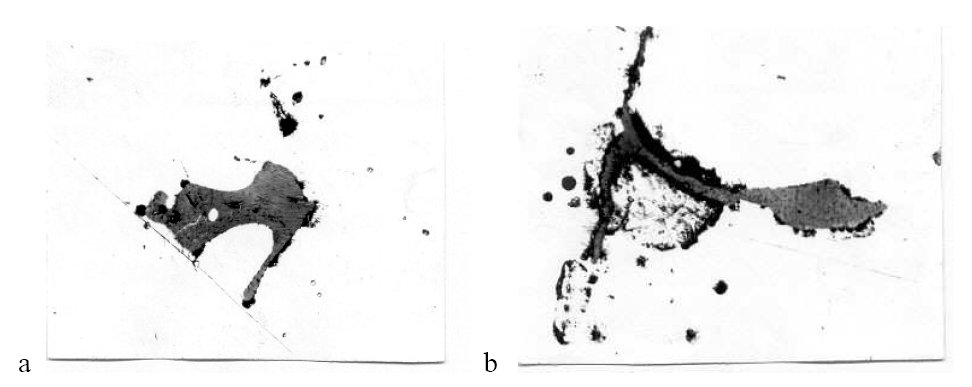

Figure 1: “Hydrogenous” cracks near sulfides in wheel steel, Mag. 600 X.

Inclusion name: Inclusion

Record No.: 857

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): No data

Inclusion type (Exogenous/Indigenous): No data

Inclusion classification: No data

Inclusion composition in weight %: No data

Sample: Wheel steel

Steel composition in weight %: No data

Note: It is well known that formation of defects of many types during railway wheels service somehow or other is connected to nonmetallic inclusions in wheel steel. Microbreakes connected with nonmetallic inclusions have different origin. The first one is “deformational”, the second is “thermal” and the third is “hydrogenous”. The objective of this work is the study of nature of microbreaking in wheel steel relative to nonmetallics. Mechanisms of microbreaking of all types near different nonmetallics had been investigated and their influence on safety threshold of railway wheels had been analyzed herein.

Fatigue cracks occur on inclusions during wear and then extend to steel matrix. The so-called “hydrogenous” cracks are associated with hydrogen content in the wheel steel that causes flake generating. In fact, inclusions are always observed in flake zone, mostly sulfides (Fig. 1). During running of steel products in hydrogen content media inclusions play the role of hydrogen collectors, since interfaces inclusion-matrix having microdiscontinuities can occlude hydrogen. Series of studies shown that inclusion as it is has no relationship with hydrogen, thus, work as its sufficient traps due to microhollows. According to this, hydrogen, having accumulated at interface and affected by internal pressure from reaction of its molization causes microbreaking near inclusions. Nature of such microbreaks depends on size of inclusion and steel matrix content determined level of its plasticity and provided either brittle or ductile opening of microcracks.

Thus, concept of no relationships between hydrogen and inclusion substance needs clarification, since series of works shown ambiguity of influence of inclusion type on hydrogenous cracking. Analysis of flakes contained in steel had shown sulfides accumulation in defected area and practically had not discovered oxide and silicate inclusions. Issue pertaining to the sulfides influence on flake generating is still open. All inclusions are capable to occlude hydrogen, but as was showed during the study, microbreakes are generated only near sulfides under different temperatures and hydrogen pressure that needs not only stresses concentration but also thermal tensile stress formation.

Additional links: Not shown in this demo version.

Reference: Not shown in this demo version.