Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Double end - Metal can defects - Coating defects

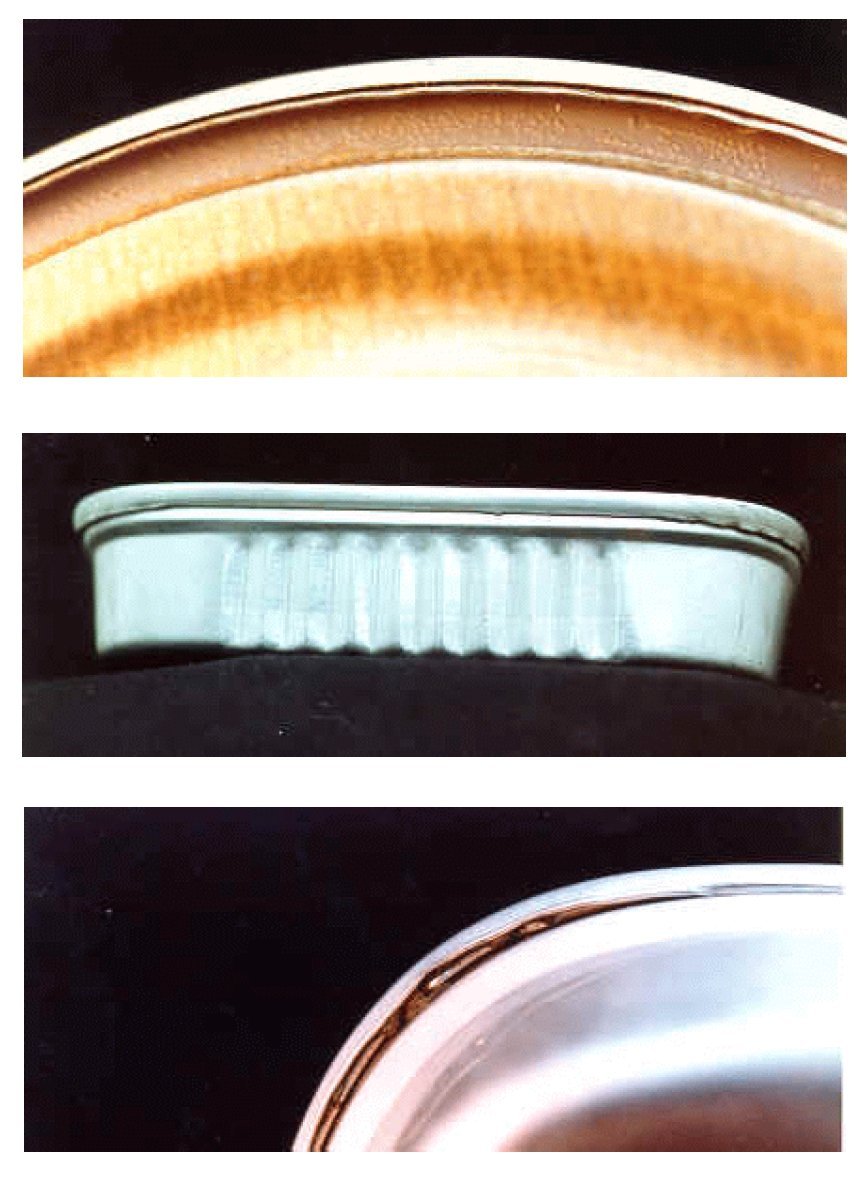

Figure 1: Double end.

Defect name: Double end

Record No.: 1494

Type of defect (Internal/Surface): Surface

Defect classification: Coating defects, metal can defects

Steel name: Steel

Steel composition in weight %: No data.

Note:

Classification: A double end is considered a serious container defect.

Description: Two ends are seamed onto one end of a can body. The double seam has the

appearance of additional thickness and length, and may have numerous droops or

vees along the double seam.

Common sources: 1. Two strips of end plate are stuck together as they enter the end press. The

resulting ends have two thicknesses of plate that are curled together and only

the inner end is compound lined.

2. Two independently formed ends are stuck together and double seamed onto a

body.

Reference: Not shown in this demonstration version.