Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Different types of cracks in bars and retired-for-cause piping welds - Welding defects

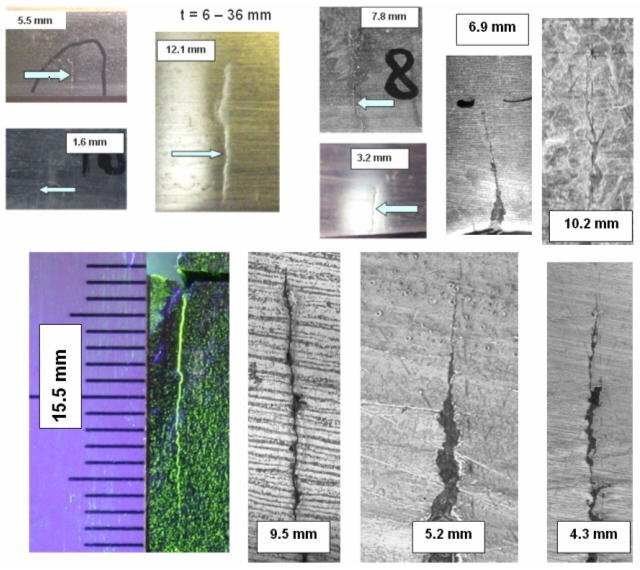

Figure 1: Different types of cracks in bars and retired-for-cause piping welds.

Defect name: Crack

Record No.: 1879

Type of defect (Internal/Surface): Internal, surface

Defect classification: Welding defects

Steel name: Steel

Steel composition in weight %: No data.

Note: A Piping Pilot Study was performed to assess the capability of detection and sizing linear defects (EDM notches and fatigue cracks), as part of Performance Demonstration Initiative for CANDU Reactor Ultrasonic Inspection. The capability and limitations of tip-echo back-scattering technique and creeping waves-mode converted technique was assessed on a large variety of piping and pressure vessel samples with OD x t = 100 mm x 6 mm - 1,200 mm x 36 mm for carbon steel ASTM 106 Gr.B, austenitic steel ASTM 308 and dissimilar welds between carbon steel and stainless steel. The influence of defect orientation, height, location, piping counter-bore slope and length, weld geometric imperfection is presented for a large variety of probe frequency and size. The ligament assessment and the minimum crack height were also evaluated.

Optical/metallographic, phased-array and magnetic particles additional techniques were used to assess the "bench-mark" crack height. Examples of crack morphology are presented in Figure 1.

Reference: Not shown in this demonstration version.