Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Fisheye - Welding defects

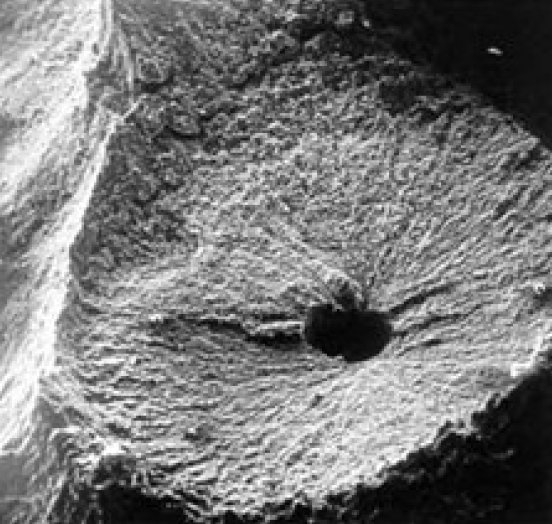

Figure 1: Fisheye.

Defect name: Fisheye

Record No.: 2259

Type of defect (Internal/Surface): Internal

Defect classification: Welding defects

Steel name: Steel

Steel composition in weight %: No data.

Note: A 'fish-eye' is seen when a ferritic steel weld metal which contains hydrogen is plastically

strained at a slow enough strain rate, at ambient temperature. The fish-eye comprises two

regions - at the centre, the 'pupil' of the eye is a pore, inclusion, or other small defect. This

is the only original imperfection associated with the fish-eye. The outer region, the 'iris',

has fractured due to local hydrogen embrittlement in a quasi-cleavage mode, in a pattern

radiating away from the 'pupil'.

There are several suggestions as to why fish-eyes form. One is that after welding,

hydrogen collects in pores and in or near inclusions. When the weld is plastically strained,

this hydrogen is released into the steel and causes embrittlement within a given radius of

the defect. A more likely explanation is that when the bulk tensile strain is greater than the

elastic limit of the hydrogen-embrittled weld metal, cracking begins at the largest defects

present. As the amount of strain increases, the test piece begins to neck, which

concentrates the strain and increases the strain rate in the necked region. The steel is no

longer embrittled by hydrogen, as this only occurs at slow strain rates. Thus, the fish-eye

crack is stopped at some distance from its origin.

It is important to test material with a hydrogen concentration representative of that which will be experienced in service,

and this should override a desire to avoid fish-eyes. However, when the primary source of hydrogen is welding, and

service loading will be some time after fabrication, it is reasonable to test after a hydrogen release treatment, or at least

by leaving test specimens in a warm place for as long as possible between welding and testing. Fish-eyes are artefacts of

testing a steel which contains hydrogen, and not defects in themselves.

Reference: Not shown in this demonstration version.