Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Thermal fatigue - Casting defects

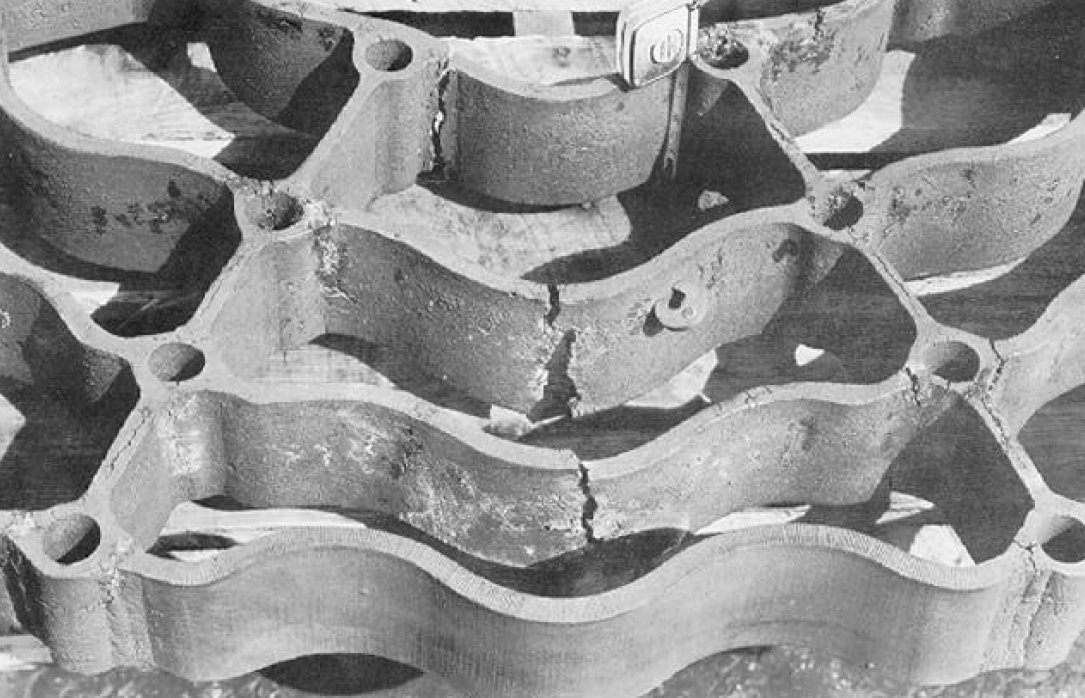

Figure 1: The effect of cast alloy surface and internal defects versus wrought alloy soundness on

service performance is illustrated by our old case history, RA330-108. The application was a

grid for suspending loads in a gantry furnace at a commercial heat treat shop. The work was

neutral hardening from temperatures up to 1850°F (1010°C), quenched in either molten salt,

oil or brine.

Defect name: Thermal fatigue

Record No.: 2391

Type of defect (Internal/Surface): Internal, surface

Defect classification: Casting defects

Steel name: Steel

Steel composition in weight %: No data.

Note: When the cast HT (35%Ni 17%Cr) grid was practically new and had been exposed to only a

few cycles, a particular job required increased working area for the grid. RA330 allo y plate

was formed and welded to the outside of the existing cast grid.

As can be seen in the photo, the cast alloy portion suffered surface attack from soot and the

quenching salt, and failed from thermal fatigue. Note the cracks in the center of the cast ribs

which occur along the plane of weakness of the dendritic structure. The wrought alloy RA330

exhibited very little surface attack and no fractures.

Reference: Not shown in this demonstration version.