Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Cracks - Rail defects

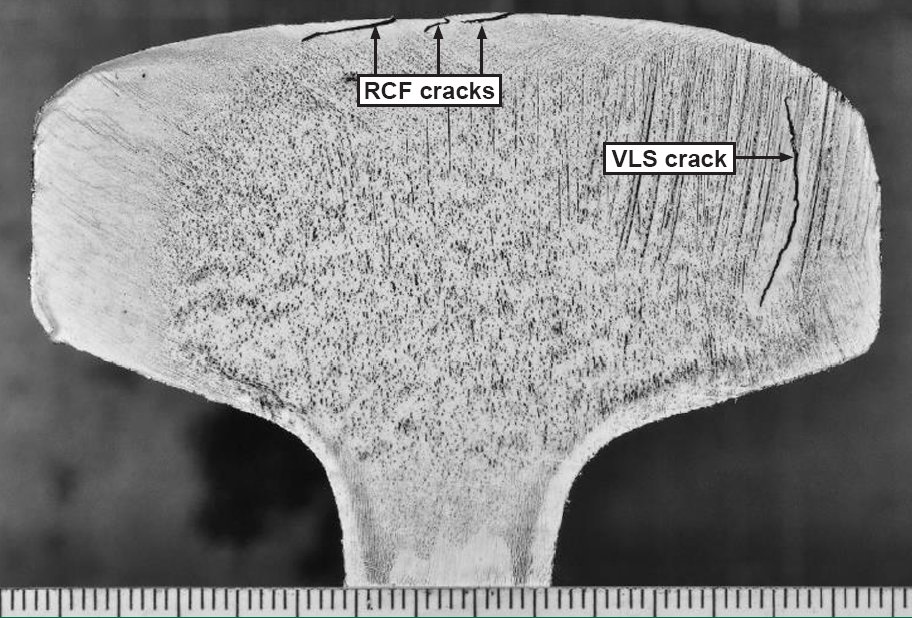

Figure 1: Magnetic particle inspection of the rail cross section at the start of the VLS section (image courtesy of Serco Rail Technical Services).

Defect name: Cracks

Record No.: 2668

Type of defect (Internal/Surface): Internal

Defect classification: Rail defects

Steel name: Steel

Steel composition in weight %: No data.

Note: The report of the metallurgical analysis of the rail fragments stated that some of the crack surfaces showed signs of corrosion, indicating that they had been exposed to the air. The report stated that this was likely to have occurred over a period of several months, indicating that the VLS crack had broken through the surface of the rail several months before the derailment. The analysis found that the RCF and VLS cracks were independent (Figure 1) and found no evidence of the VLS crack growing up into the area of RCF cracking near the rail head, but the crack had broken through the upper fillet radius in several places. The crack surfaces were smooth, showing that the pieces of rail each side of the crack had rubbed against each other, smoothing off the crack surface. This relative movement could only occur if the rail was loaded in bending after the crack had formed, showing that the crack had been in the rail for some time. On the basis of the corrosion that had occurred to some of the fracture faces, it is possible that the crack had broken through the surface before the inspections by the asset engineer, section manager (track) and ultrasonic team in July 2014.

Reference: Not shown in this demonstration version.