Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Flakes - Tool steels - Heat treatment defects

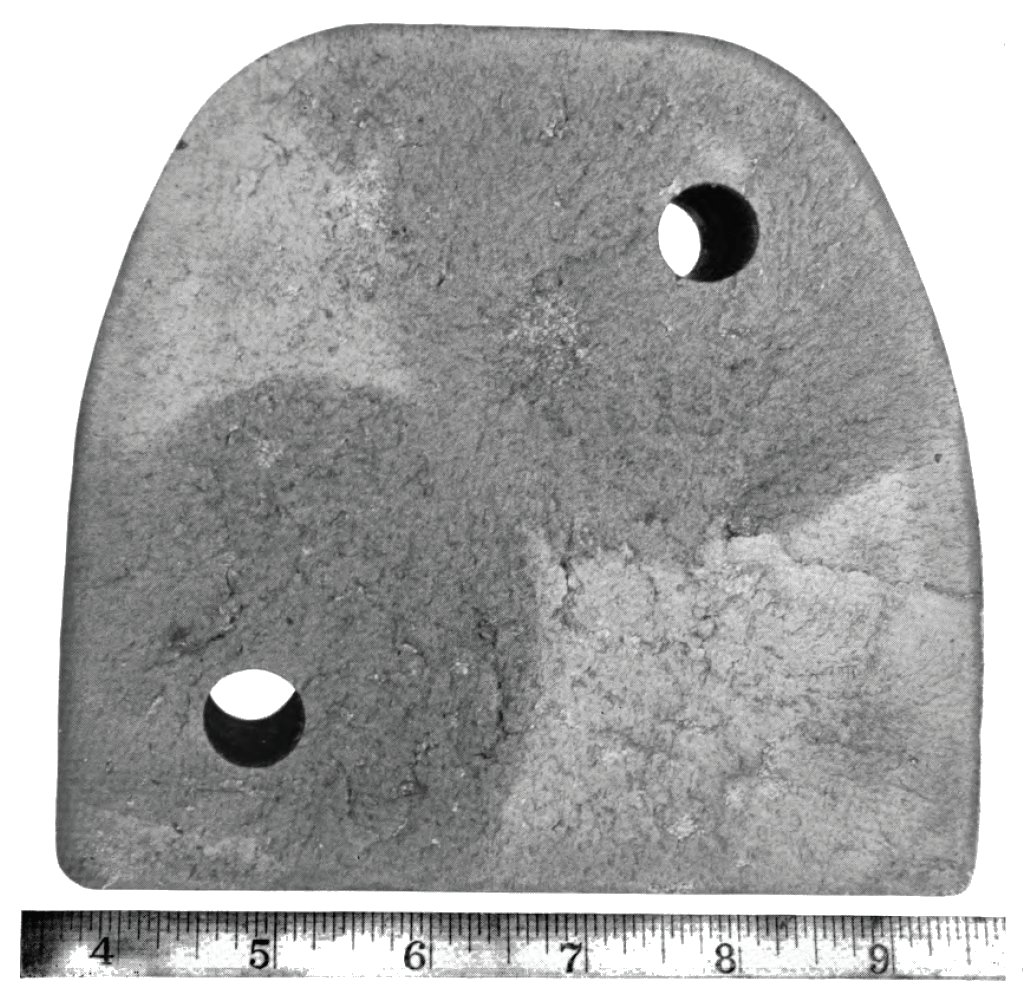

Figure 1: The fracture of this 6-in.-square die made of carbon tool steel occurred in hardening

because of internal cooling cracks (flakes) present in the steel. This condition is

due to improper cooling of the steel after the last rolling or forging operation.

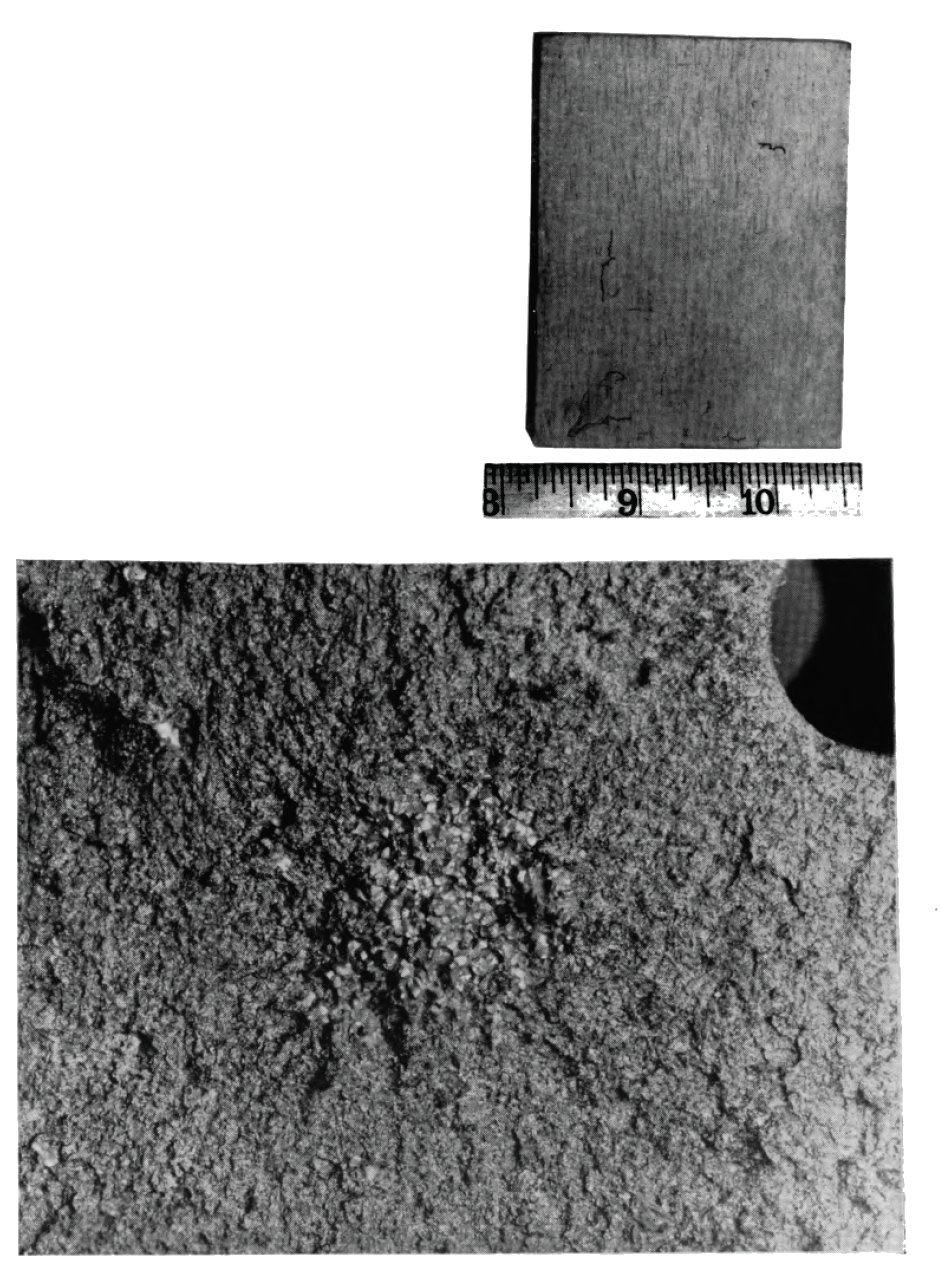

Figure 2: Top: The appearance of flakes is evident on this acid-etched section of the die shown on the Fig. 1. Bottom: Enlarged view (3 1/2 x) of a portion of the fracture shown on Fig. 1. Coarse crystalline grains indicate the flakes. Note that the flakee shows coarse, unrefined crystallinc grains as compared to the fine grains of the adjacent areas.

Defect name: Flakes

Record No.: 2870

Type of defect (Internal/Surface): Internal

Defect classification: Heat treatment defects, fractography

Steel name: Tool steel

Steel composition in weight %: No data.

Note: No data.

Reference: Not shown in this demonstration version.