Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Wear tracks - Hard Cr coating - Coating defects

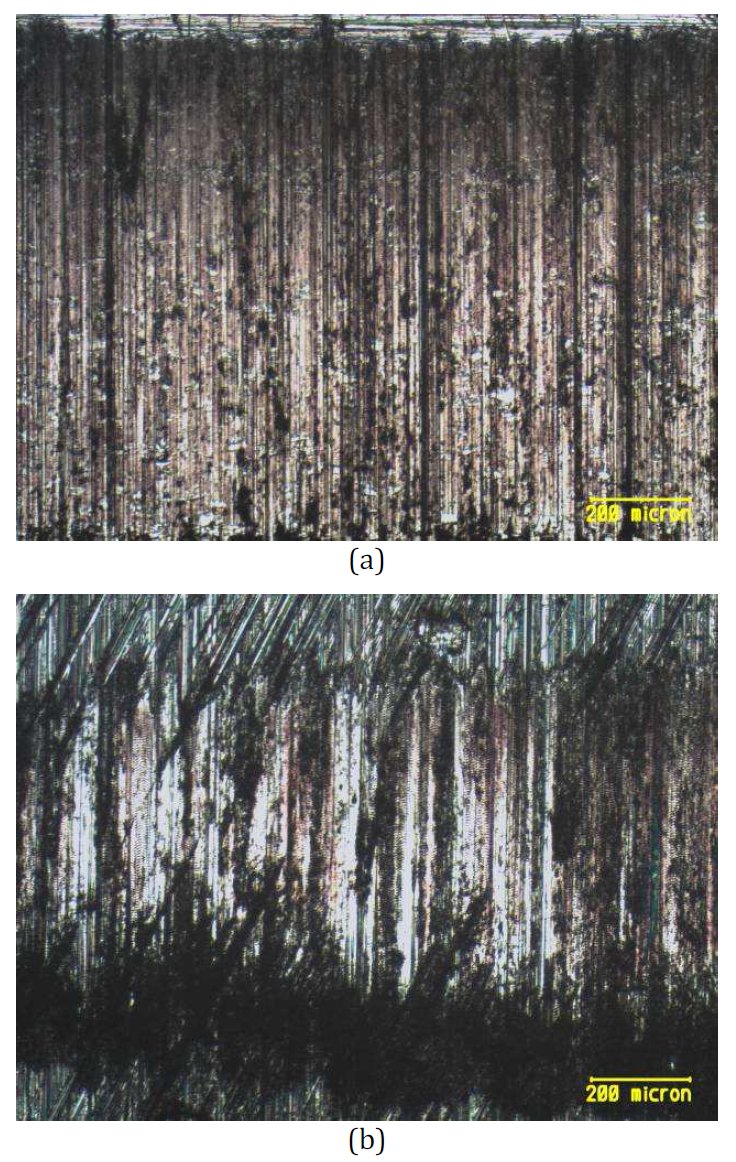

Figure 1: Wear tracks after sliding distance of 200 m,

normal load value of 30 N and sliding speed of 1 ms-1

(a) without coating; (b) hard Cr coating.

Defect name: No data.

Record No.: 2943

Type of defect (Internal/Surface): Surface

Defect classification: Coating defects

Steel name: Steel

Steel composition in weight %: No data.

Note: Primarily we should say that adhesive wear occurs

when the contact pressure between sliding

surfaces is high enough to cause local plastic

deformation and welding between the contacting

asperities. Abrasive wear, however, occurs

between two hard sliding surfaces when hard

debris particles are indented and make grooves in

the sliding surface of the material. Both kinds of

wear can be lessened by either a decrease on the

contact pressure or an increase in the mechanical

strength of the material itself. Fig. 1 presents wear

tracks of tested samples in the conditions without

lubrication and after sliding road of 200 m.

Displayed tracks in Fig. 1 are created in condition

of the highest sliding speeds and maximum normal

load in this test. Based on the appearance of wear tracks, we can conclude that the dominant wear

mechanism is abrasive wear.

Reference: Not shown in this demonstration version.