Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Rippled surface - Ingot defects

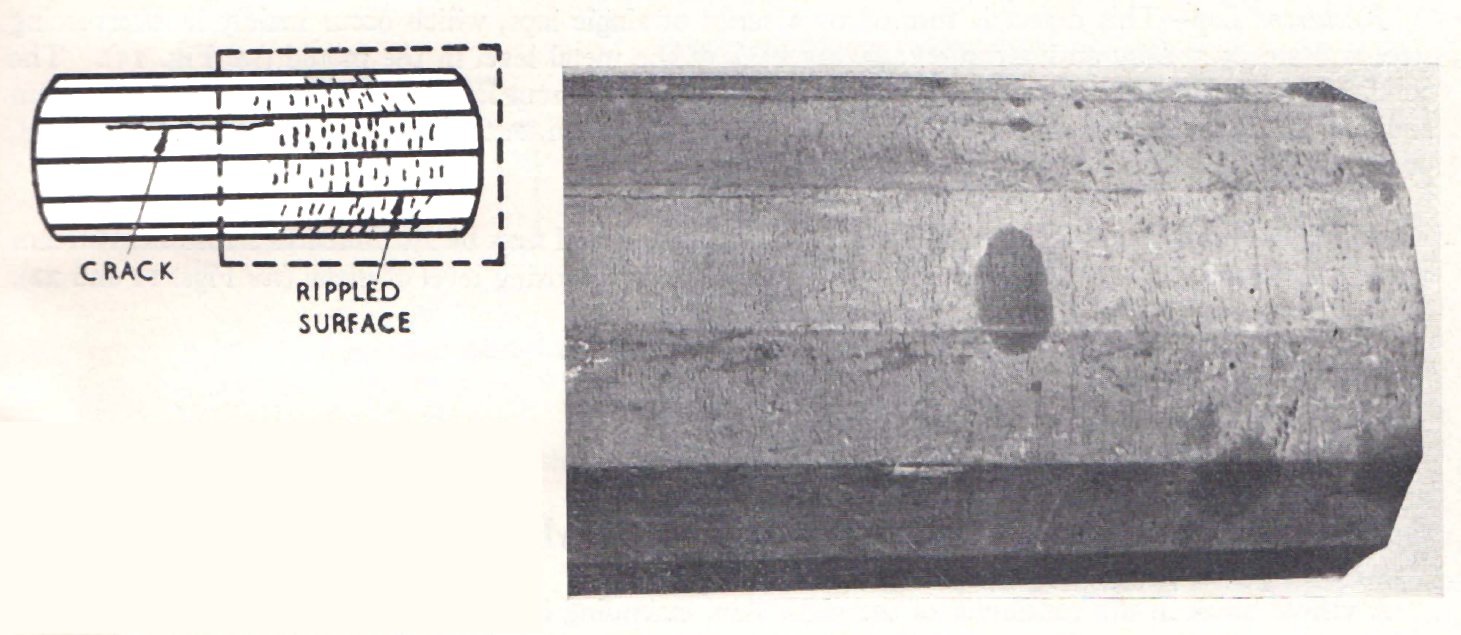

Figure 1: Rippled surface at the top end of a duodecagonal ingot of a plain-carbon killed steel. Note also longitudinal corner crack.

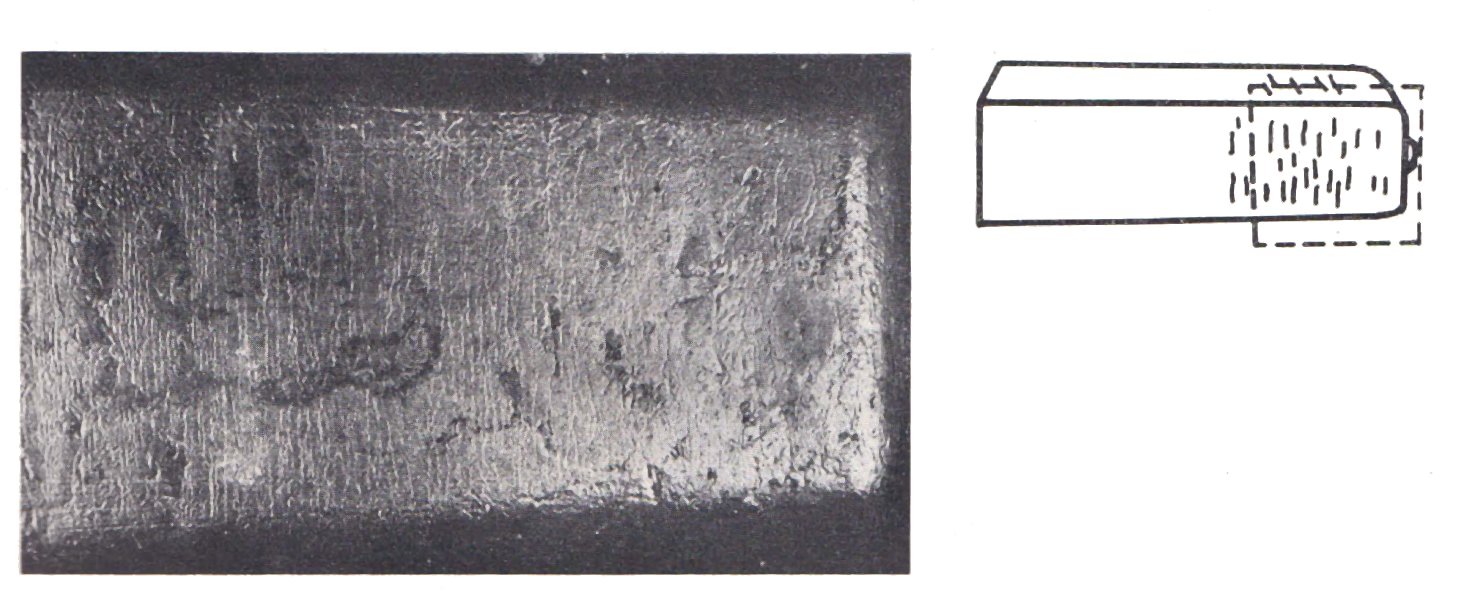

Figure 2: Rippled surface on a bottom-poured ingot of alloy steel.

Defect name: Rippled surface

Record No.: 300

Type of defect (Internal/Surface): Surface

Defect classification: Ingot defects

Steel name: Steel

Steel composition in weight %: No data.

Note: A series of slight peripheral undulations on the ingot surface caused by a rapid succession of layers

of frozen metal forming near the mould walls, and becoming engulfed in turn as teeming proceeds. The defect is characteristic of metal which has been teemed at a too low temperature, or, where the temperature is normal, at a too low teeming rate. It may also occur when the mould surface condition is such that a very heavy and variable drag on the rising metal is caused. Examples are shown in Figs. 1 and 2. In slight forms, a rippled surface is not considered to be a defect, as it has no deleterious effect on the rolled product. It can be considered as a mild form of lapping, and rippled ingots

are often lapped towards the top end. The defect is sometimes termed 'crusting and lapping'.

Reference: Not shown in this demonstration version.