Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Burst at the bulging - 1.7709 steel - Cold drawing defects

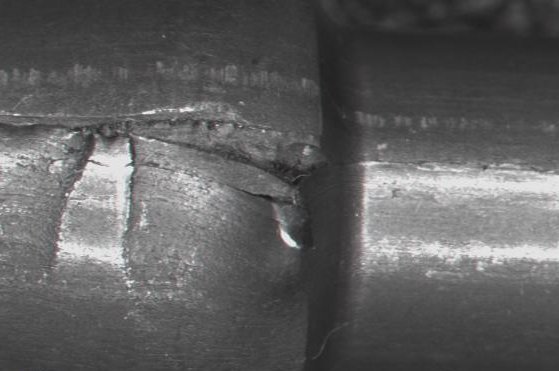

Figure 1: Treatment: Spheroidised. Magnification: 6.5x. Sampling/Specification: Bulge area - sample 1. Testing result: Through a surface defect the bulge part is burst.

Figure 2: Treatment: Spheroidised. Magnification: 16x. Sampling/Specification: Wire surface - sample 2. Testing result: Surface defect in longitudinal direction.

Defect name: Burst at the bulging

Record No.: 429

Type of defect (Internal/Surface): Surface

Defect classification: Cold drawing defects

Steel name: 1.7709 steel

Steel composition in weight %: No data.

Note: It can come to bursts at the wire surface of cold upsetting steels by the compressing to screws or tools. The strength of the bursts is dependent from the degree of the cold forming, the size of the existing defects and possible anomalies of the structure. A pincher and pre-material defects, with an slag in surface proximity, were the reason for the processing problems in this case.

Rod wire 12.00 mm round - pickled, annealed.

Reference: Not shown in this demonstration version.