Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Stress crack at the wire - 1.7707 steel - Cold drawing defects

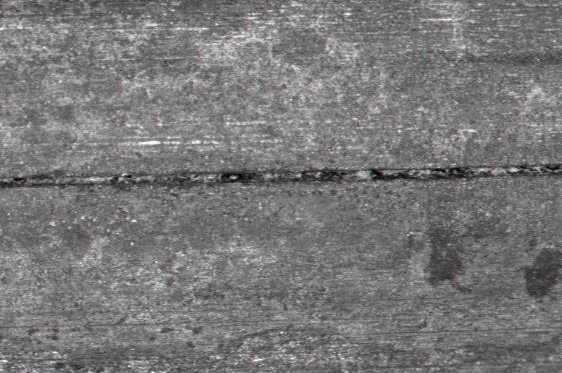

Figure 1: Treatment: Quenched and tempered. Magnification: 2x. Sampling/Specification: Wire surface. Testing result: Longitudinal defects on the surface.

Figure 2: Treatment: Quenched and tempered. Magnification: 6.5x. Sampling/Specification: Wire surface. Testing result: Longitudinal defects on the surface.

Defect name: Stress crack at the wire

Record No.: 434

Type of defect (Internal/Surface): Surface

Defect classification: Cold drawing defects

Steel name: 1.7707 steel

Steel composition in weight %: No data.

Note: Stress cracks can occur in different forms. At the rod wire or steel bar they usually go in longitudinal direction and could be able to reach the core zone. They are often also only few hundredth millimeters deep. If the defects are very deep they are often wide open. However, there also are cases, particularly at drawn materials, where the cracks almost aren't recognizable on the surface. A stress crack can arise from too curt cooling after hardening or by unfavorable conditions after the hot forming. Smaller defects (rolling defect or slags in surface proximity) are often triggers for stress cracks on the material surface. In the following sample the crack became triggered so.

Rod wire 18.00 mm round - quenched and tempered, pickled.

Reference: Not shown in this demonstration version.