Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Pincher - 1.4016 steel - Cold drawing defects

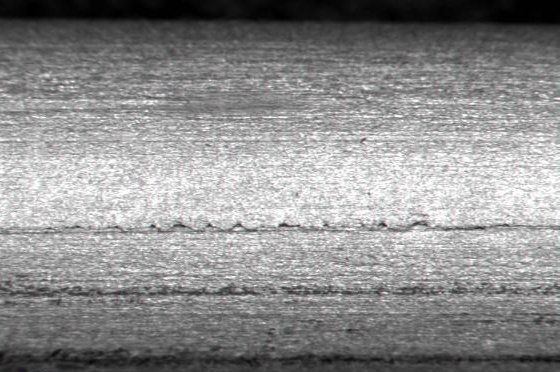

Figure 1: Treatment: Soft annealed. Magnification: 6.5x. Sampling/Specification: Wire surface. Testing result: Longitudinal defects on the surface.

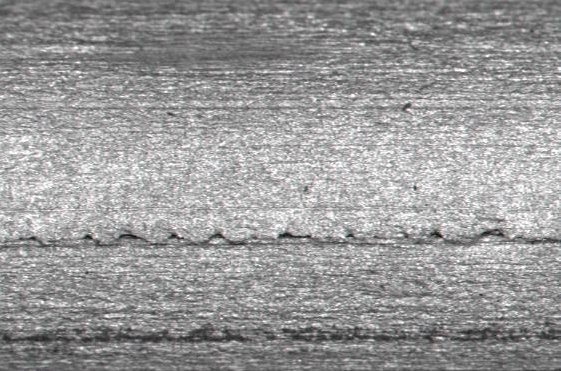

Figure 1: Treatment: Soft annealed. Magnification: 10x. Sampling/Specification: Wire surface. Testing result: Longitudinal defects on the surface.

Defect name: Pincher

Record No.: 435

Type of defect (Internal/Surface): Surface

Defect classification: Cold drawing defects

Steel name: 1.4016 steel

Steel composition in weight %: No data.

Note: Pinchers are defects which occurs during rolling the billet or block to the wire or steel bar. Rolling fins, which were pressed in again during the subsequently rolling process, are a cause for example. Strong grooves at the semi finished products (billet) also can lead to pinchers, if they are pressed together during rolling to the profile. The defect can occur locally or about the complete rod wire length. Looked about the extent, the defect can be existing on one side or also transposed by 180°.

Rod wire 6.00 mm round - annealed, pickled.

Reference: Not shown in this demonstration version.