Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Blow holes and open blows - Casting defects

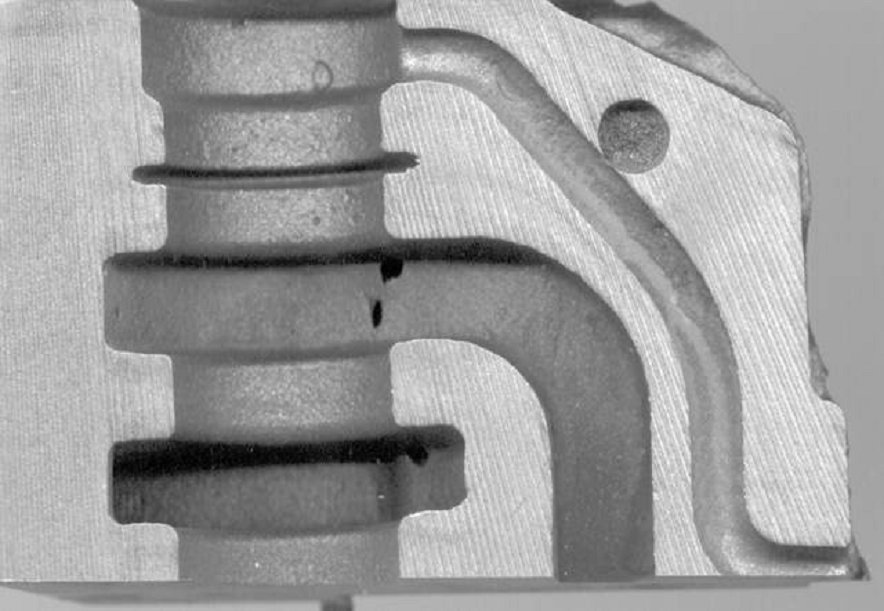

Figure 1: Blow holes and open blow.

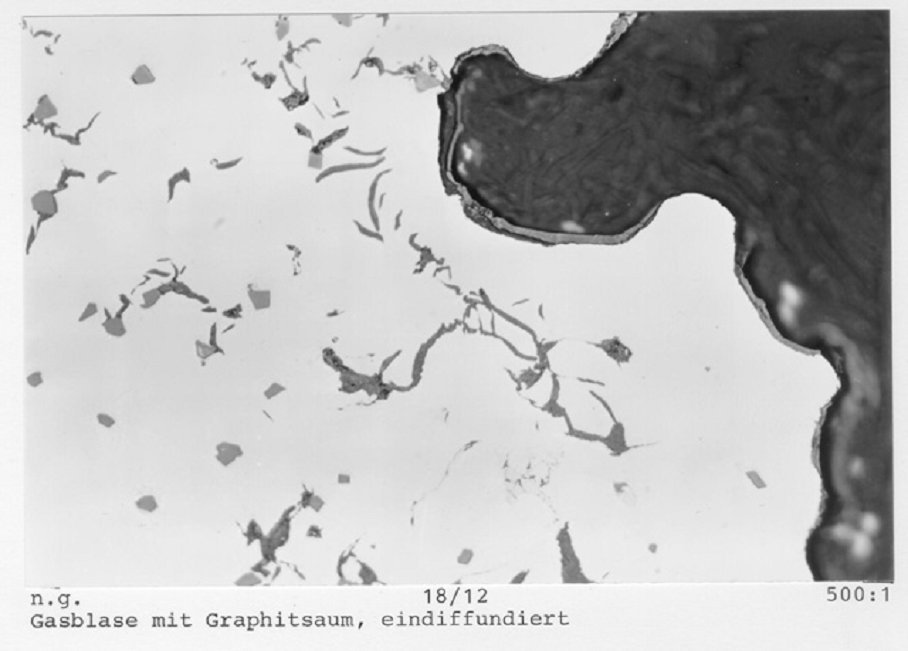

Figure 2: Blow holes and open blow.

Figure 3: Blow holes and open blow.

Defect name: Blow holes and open blow

Record No.: 855

Type of defect (Internal/Surface): Surface

Defect classification: Casting defects

Steel name: Steel

Steel composition in weight %: No data.

Note:

- Cavities, mostly with smooth walls; bright or oxidised.

- In the case of large blowholes with corrugated walls too. Always spherical form, even in large expansions (then always flat cavities). Frequently accompanied by slags and oxides.

Typical characteristics: Rounded shapes, location always in the upper part of the

castings and beneath cores or undercuts. Individual blow holes or large accumulations, then mostly with different sizes.

Preferred defect locations: In parts of the casting in the top of the mould, often above larger cores. In thick parts, but also in thin walls. Beneath undercuts and large cores.

Apart from presence of moisture, they occur due to poor venting and lower permeability of the mold.

Remedial measures:

- Adequately dry cores,

- Larger proportion of new sand,

- Better gas permeability,

- Smaller proportion of binder,

- Check casting system,

- Reduce moisture content of the sand,

- Add a little oxide to the melt (e.g. rusty insert).

Reference: Not shown in this demonstration version.