Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Hydrogen microprinting

Hydrogen microprinting was used to detect and observe the location of hydrogen

accumulation in pipeline steel by modifying the procedure developed by Ovejero-Garcia.

Initially, the sample was polished to 0.05 micron finish and etched with

2% nital enchant in order to reveal the microstructure. The etched surface was then

coated with Corona Dope Red X insulating varnish to eliminate the possibility of

corrosion on the surface that would be examined. The other side of the steel sample was

then used to charge hydrogen in 1 N NaOH solution with -1.5 VSCE for three hours. This

time was considered sufficient in order to allow hydrogen to diffuse completely through

the sample to be detected at the coated surface. After three hours, the sample was

removed from solution, and the coating was removed from the sample with acetone. The

sample was then lightly polished at 0.05 micron to remove hydrogen adsorbed on the

surface and ensure that all coating was removed. The sample was then rinsed with

acetone again to make sure the surface was free from oil, grease or debris. Once the

sample was clean, the microprinting process began where care was taken to reduce the

amount of time in-between charging and microprinting.

In a dark room under red light, the microprinting was accomplished by initially

coating the sample with 1 g Ilford L-4 nuclear emulsion, with a grain size of 140 nm,

diluted into 2 mL of 5% wt solution of NaNO2. The addition of NaNO2 reduces spurious

corrosion and false accumulation of silver grains. After dilution the solution was heated

to 45 C and held for 20 minutes to achieve homogenization. The solution was cooled to

room temperature prior to application. Care was taken not to heat the solution to 50 C as

it would breakdown the emulsion. The dark room environment was necessary as the L4

emulsion is sensitive to natural light. Exposure to blue range wavelengths would produce

a latent image that would obscure any detection of hydrogen atoms.

To achieve a monogranualr layer of AgBr crystals, the emulsion was applied

using the wire loop method. The wire loop method is accomplished by means of

0.2 mm diameter wire that forms a loop of 3 cm diameter. Once the emulsion is applied

to the surface, the loop is kept on the sample until the emulsion hardens into a gel

consistency. Time taken for the hydrogen to diffuse through the metal and affect surface

detection previously determined to be roughly one hour. The expected reaction at the

steel surface between silver bromide and hydrogen is:

AgBr + H -> Ag(s) + HBr

Subsequently, the emulsion was removed from the sample after one hour of exposure.

The "fixing" stage in this experiment involves the removal of excess HBr in order

to observe deposited silver grains. In this process, the sample was soaked in a solution

with 250 g sodium hyposulphite + 10 g sodium sulphite + 50 mL sodium bisulphate + 30 g

NaNO2 + distilled water to make the total solution volume to one liter. The sample

was soaked in fixing solution for 3 minutes and then rinsed with distilled water for 30

seconds three times. The sample was then hot air dried and observed under SEM. Silver

grains, approximately 10 nanometers in size, are observed at the locations of hydrogen

traps near the surface. Samples not subjected to hydrogen charging were also

microprinted to verify the technique and verify the accuracy of silver grain deposition.

To validate the sites of trapping in the studied microstructures, hydrogen

microprinting was performed. In the hydrogen microprinting process, silver bromide is

deposited on the surface of a sample to undergo a chemical reaction with trapped

hydrogen near the surface of the sample. Hydrogen will react with the bromide leaving

deposits of nano-silver grains wherever hydrogen was once trapped.

It was determined through experimentation that the microprinting technique could

only be accomplished on ferrite-pearlite structures. This is because it was impractical to

distinguish silver grains from carbides in tempered and water quenched samples as the

silver grains had the same brightness and morphology when viewed by SEM. Further,

observation of small scale silver grains was obstructed by carbides charging.

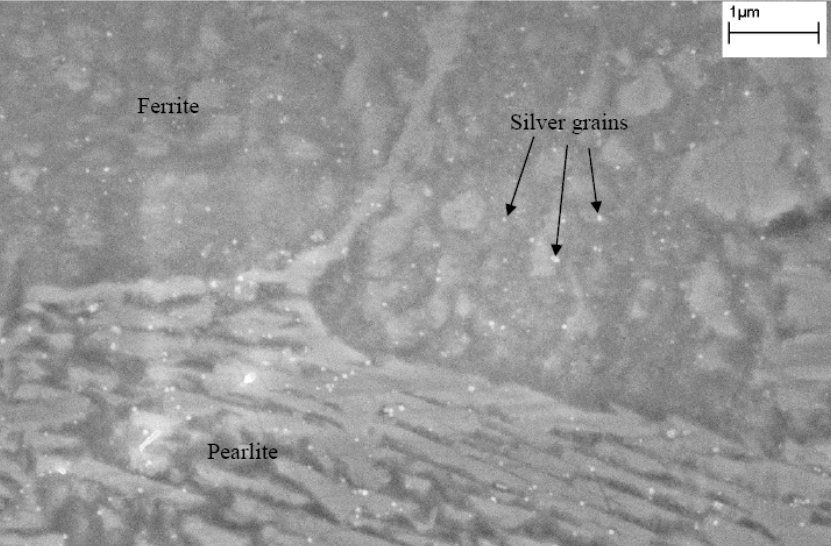

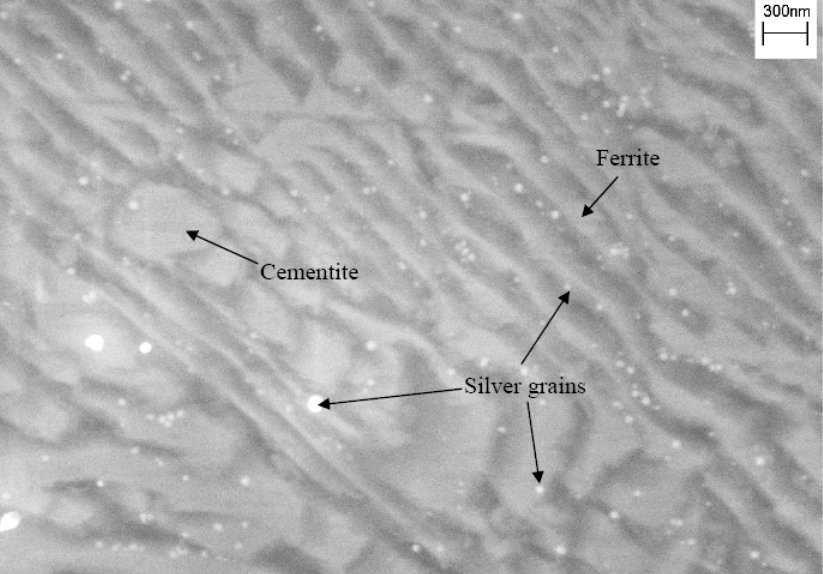

Microprinted as-received sample is shown in Figures 1 and 2. Silver particles

are approximately 10 nm and appear bright and imposed on the microstructure. Samples

that were microprinted but not exposed to hydrogen did not show any of these silver

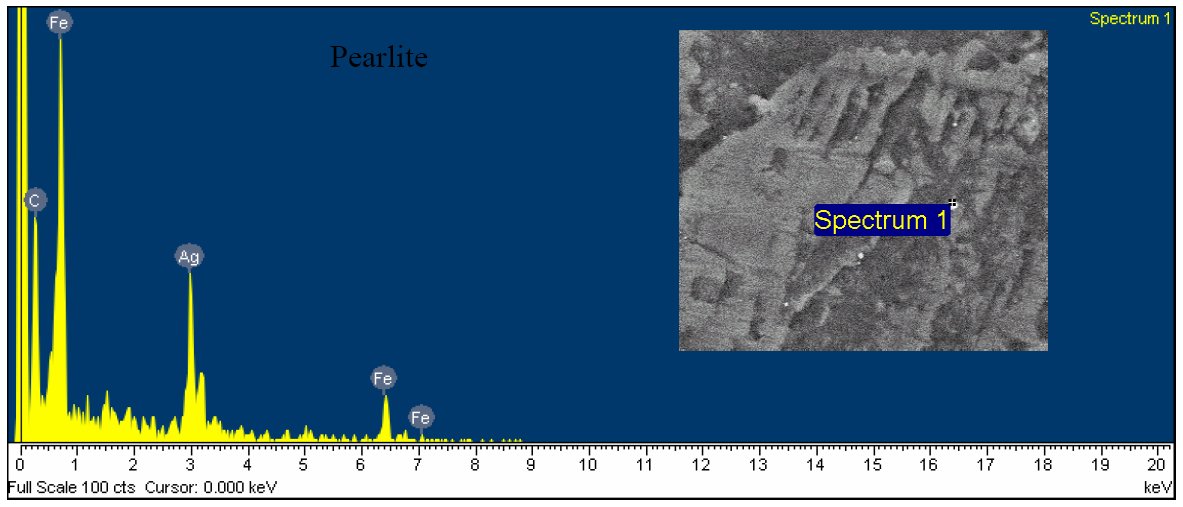

grains. EDS was performed on these grains to confirm the presence of silver and results

are given in Figure 3. Figure 1 demonstrates that the hydrogen accumulated evenly

throughout the ferrite and pearlite grains, providing further evidence of lattice diffusion.

Figure 2 shows that within the pearlite, hydrogen accumulates in the ferrite structure as

compared to the cementite. Within the ferrite grain, the hydrogen is most likely trapped

by the dislocations and interfaces. Within the pearlite grain, the hydrogen is most likely

trapped by the cementite-ferrite high energy interfaces.

Figure 1: SEM of hydrogen microprinted as-received sample. Scale bar: 1 µm.

Figure 2: SEM of hydrogen microprinted as-received sample. This image shows that hydrogen preferentially accumulates in the ferrite as oposed to cementite in pearlite grains. Scale bar: 300 nm.

Figure 3: EDS results for silver particles to confirm the hydrogen microprinting.

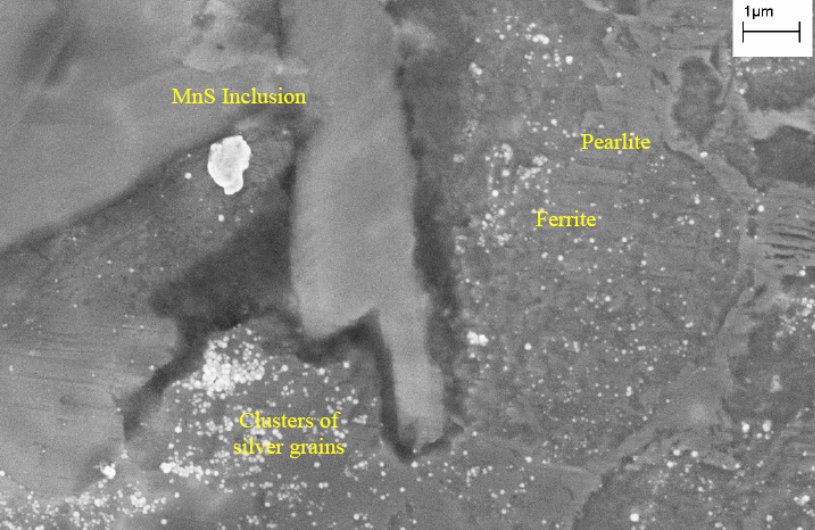

Microprinting was also performed on normalized pipeline steel samples and the

results are given in Figure 4. In this sample, very little hydrogen was observed in the

pearlite grains. Rather, most silver grains, and associated hydrogen, was located in the

ferrite grain. The concentration of these sliver grains was significantly less than in the asreceived

sample. Contrary to permeation results, this indicates that the trapping

concentration in the normalized sample is less than the as-received. This indicates that

hydrogen is most likely trapped by dislocations within the ferrite grain. The decrease of

silver grains in normalized sample exhibit the decrease in dislocation density and trap

sites, causing in increase in diffusivity.

The normalized sample also exhibited the effect of hydrogen distribution around

inclusions, as shown in Figure 5. Around the inclusion, hydrogen occurred in high

concentrations in comparison to the bulk sample. The inclusions were determined to be

MnS by EDS. This accumulation of hydrogen is attributed to the interface and high

dislocation density that develops around an incoherent inclusion/precipitate. This

confirms the previous assertion that interfaces and dislocations act as hydrogen traps.

Subsequently, pipeline steels that have lower concentrations of inclusions should have

high hydrogen diffusivity.

Figure 4: SEM of hydrogen microprinted annealed sample. As compared to the as machined sample, the annealed sample has a significantly less hydrogen. However the preference of hydrogen to accumulate within ferrite is still apparent. Scale bar: 1 µm.

Figure 5: Hydrogen concentration around a MnS inclusion was much higher than what was observed in the bulk of the sample. Hydrogen concentration around a MnS inclusion was still concentrated in ferrite grains rather than pearlite. Scale bar: 1 µm.

Reference: Stefanie Lynn Asher, Investigating the Mechanism of Transgranular Stress Corrosion Cracking in Near-Neutral pH Environments on Buried Fuel Transmission Pipelines, Georgia Institute of Technology, School of Materials Science and Engineering, PhD Thesis, 2007, pp. 78-80, 113-119.