Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Chicken cracks - Grinding cracks - Machining defects

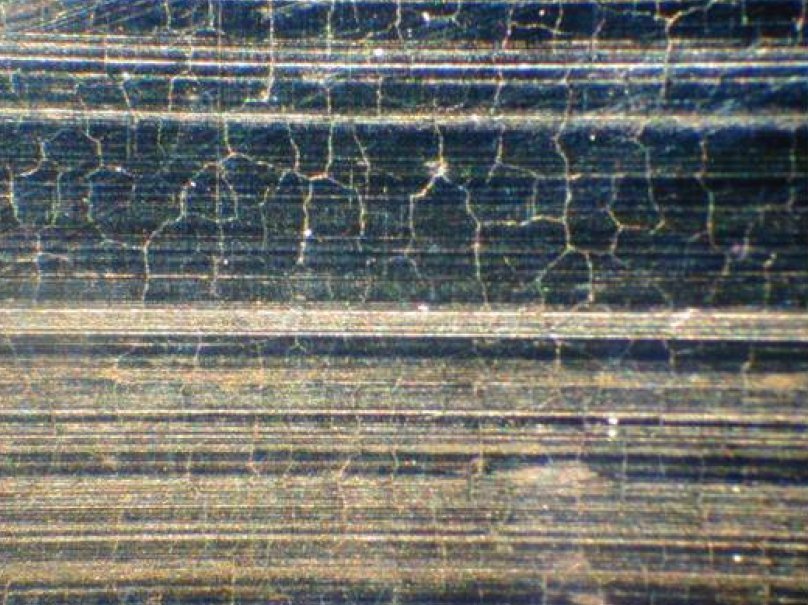

Figure 1: "Chicken cracks" caused by excessive grinding pressure and/or insufficient lubrication.

Defect name: Grinding cracks

Record No.: 1899

Type of defect (Internal/Surface): Surface

Defect classification: Machining defects

Steel name: Steel

Steel composition in weight %: No data.

Note: The stripping of electrodeposited and flame-sprayed coatings is a

necessary part of surface finishing. Stripping may be required to allow for

the re-plating of a part rejected due to defective finishing or as part of

rework processes such as those commonly conducted by

airline/aerospace facilities. This paper discusses stripping methods and

operational considerations in their use.

It is important that we point out that mechanical means can be and often are also utilized to

remove organic and inorganic coatings, especially when the part shape makes the application of

abrasive methods practical. Mechanical finishing may also be employed in addition to chemical

stripping to produce a more uniform surface finish on the stripped part and/or to remove smut

and other residues that may be left behind by chemical methods.

Blasting, machining, grinding and vibratory finishing are the most commonly employed

mechanical methods of stripping or treating parts after chemical or electrochemical stripping.

Machining and grinding are commonly employed methods of stripping or finishing parts with

simple geometries, such as shafts and cylinders, while blasting is employed on more complicated

part shapes.

In the airline / aerospace industry, equipment manufacturers provide specifications that describe

the approved methods of mechanical stripping/finishing. These must be carefully followed since

machining and grinding in an uncontrolled manner can cause surface defects before and after

re-plating. As an example, Boeing has reported that grinding the stripped surface of a part by

using too much pressure and not enough lubrication can cause "chicken cracks" to appear in the

hard chromium deposit (Fig. 1).

Reference: Not shown in this demonstration version.