Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Flat shoulder tool welded plate - Welding defects

Figure 1: Appearance of flat shoulder tool welded plate.

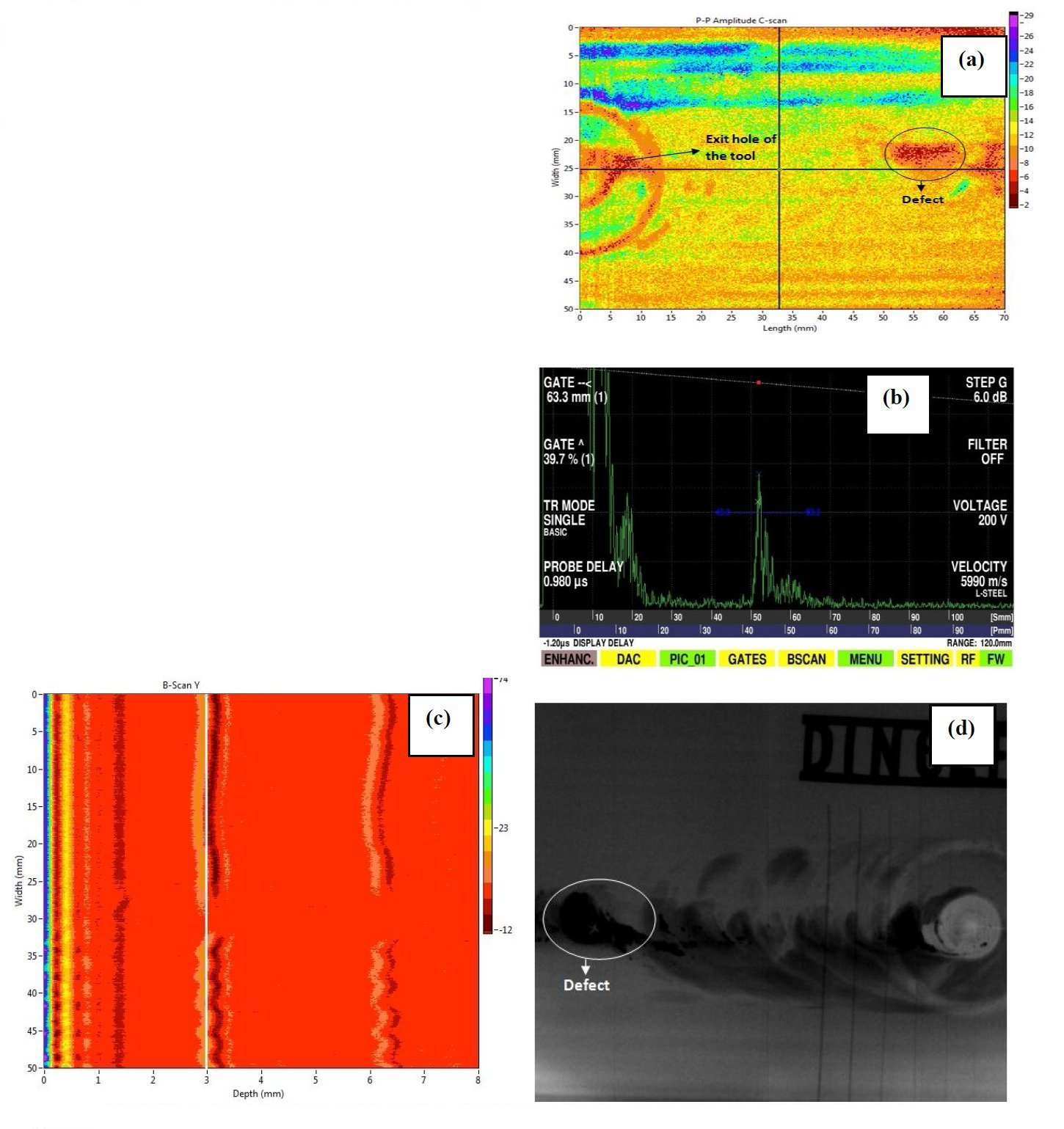

Figure 2: Flat shoulder tool welded plate (a) C scan (b) A scan (c) B scan (d) Radiography.

Figure 3: Appearance of concave shoulder tool welded plate.

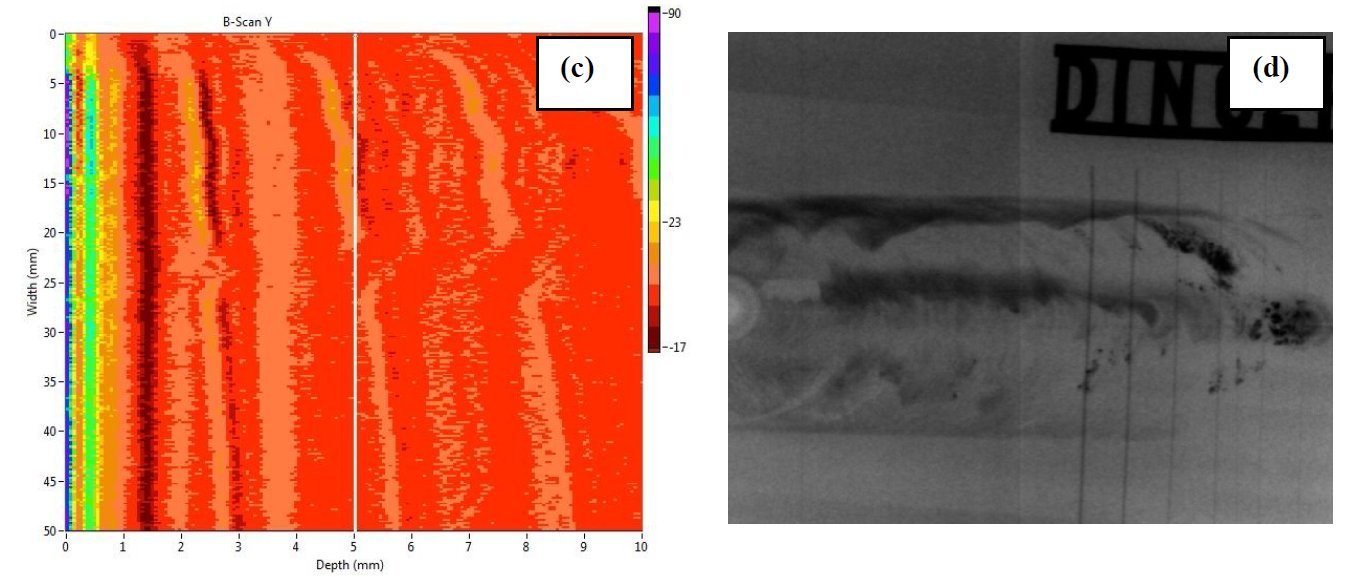

Figure 4: Concave shoulder tool welded plate (a) C scan (b) A scan (c) B scan (d) Radiography.

Figure 5: Appearance of Sub shoulder welded plate.

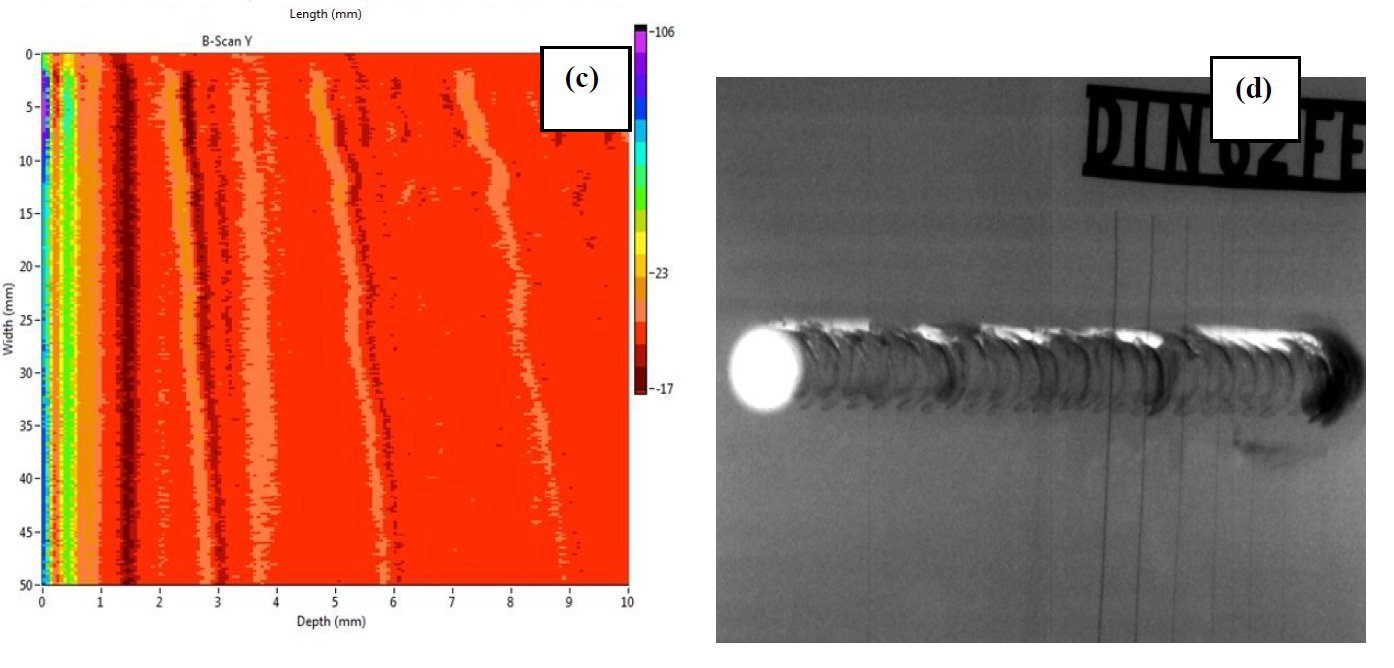

Figure 6: Sub shoulder tool welded plate (a) C scan (b) A scan (c) B scan (d) Radiography.

Defect name: Voids

Record No.: 1914

Type of defect (Internal/Surface): Internal, surface

Defect classification: Welding defects

Steel name: Steel

Steel composition in weight %: See the text bellow.

Note: Tool design in Friction stir welding (FSW) of steel is a critical problem and hence experiments were carried on

with three combinations of tool profiles having tapered pin, concave and flat shoulders. The study of tool wear resulted in a

new finding of Sub shoulder tool and gave reduced tool wear. The tool wear is indirectly being reduced by using a shorter

pin length of 2.6mm. Rupture of material surfaces which were in contact created reduction in the tool geometry and defect

on welds were obtained. Based on the tool shape corresponding to its weld length, defects were occurred in the weld zone.

This study is concentrated on finding the possible defects during welding by using different tool profiles using ultrasonic,

radiography and thermography techniques. It was observed from the weld that the flat shoulder gave improper joining

defects while the concave shoulder gave reduced defects when compared to flat shoulder, and the Sub shoulder is defect free.

Friction stir butt weld was conducted using IS:

3039, grade II (0.204 wt% C, 0.129 wt% Si, 1.10

wt% Mn, 0.309 wt% Cr) low alloy steel plates,

having dimensions of 100 x 50 x 3 mm. A modified

vertical milling machine was used to perform this

Friction Stir Welding (FSW) processes. In this

investigation Tungsten alloy tool (W-5.7908Ni-

3.2318Fe-0.2228Mo-0.1214Co-0.0709O2 wt-%) was

used to perform the tool wear study. Shorter pin

length of 2.6 mm, shoulder diameter of 25 mm, and

pin diameter of 12mm at the root and 4 mm at the tip

were maintained as constant.

Flat shoulder tool: The surface of flat shoulder will be completely been

in contact with the work piece surface. The frictional

contact of this flat surface might produce higher

temperature, which makes the material to its plastic

material flow quickly. In terms of tool wear for steel

plates, this flat surface rubs over the interface surface

and results in higher tool wear rate when compared to other profiles. Defective Weld is formed by using this

flat shoulder. Appearance of welded sample is shown

in Fig. 1.

The surface of the welded sample found to

have voids on the upper surface itself. At the bottom

of the welded plate, there is a root defect. The marked

region opposite to the exit hole shows higher

attenuation, which represents the defect in the particular region as shown in Fig.2 (a) and this, is the

C – scan image of flat shoulder.

The defect is a void shown in a circle. The defect is at

a depth of 2.8 mm which is shown in the A – scan

image of Fig.2 (b). In the weld length, at 25mm cross section as shown in

Fig.2(c) indicates the defect region with a variation in

the signals. The B – scan image shows the defect is at

a depth of 2.8 mm and size of the defect is 11 x 5mm.

The radiograph reveals that there is void at the

marked position as shown in the Fig.2 (d).

Sub shoulder tool: During the experiments conducted on concave

shoulders, a step like formation was naturally

occurred and this was developed as a new tool design

tool and has been named as sub shoulder. It was

found that the tool could produce 1200 mm length of

weld, which was the highest weld length among the

other tools that could travel. The welded plate by sub

shoulder tool is shown in Fig.3 and found with defect

free.

Concentric circles can be seen over the plate

surface. This is the metal flow because of first mode

of metal transfer, as shown in Fig.4 (a) and roughness

in surface is clearly seen in A-scan image of Fig.4

(b). However, the welded plates are found to befree

from defects along the thickness of the weld, and this

is assured from the B-scan image as shown in

Fig.4(c). Ultrasonic images show that there is no

defect along the weld length.

Exit hole is visible on the radiograph as shown in

Fig.4 (d). Except the initial plunge impression of tool From the results of NDT techniques, Sub shoulder

tool is found to be free from defects. Flash on welded

plates cannot be considered as defect, if it is in

allowable limits and this does not affect the weld

formation. All the welded plates of flat shoulder were

found with tunnel defect and surface irregularities.

Lack of material flow and poor tool design are the

reasons for such defect. Among the tool profiles, flat

shoulder tool is found to give maximum number of

defects.

Reference: Not shown in this demonstration version.