Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Fatigue failure (pitting) - Gear defects - Other defects

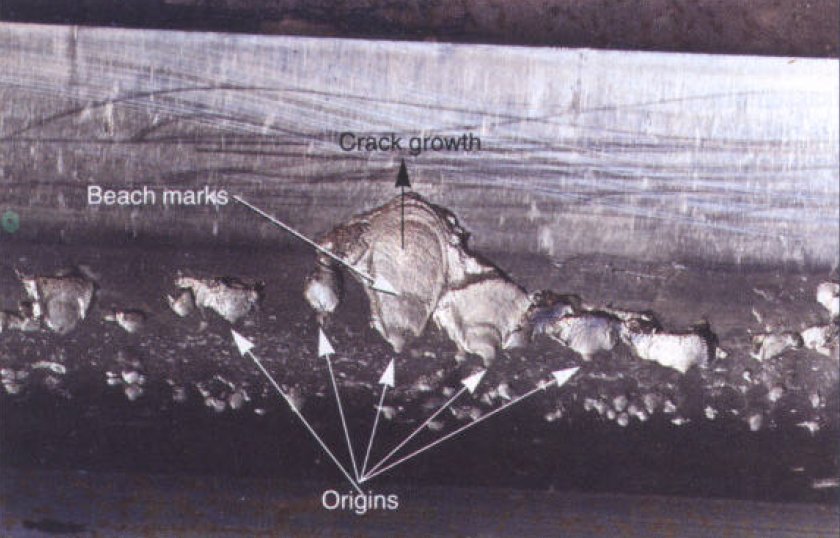

Figure 1: Fatigue failure (pitting) in the

contact surface of a gear tooth.

Beach marks are visible in some of

the larger pits.

Defect name: Fatigue failure (pitting)

Record No.: 2094

Type of defect (Internal/Surface): Surface

Defect classification: Gear defects, other defects

Steel name: Steel

Steel composition in weight %: No data.

Note: When an important gear failure occurs,

someone becomes responsible for

analyzing the failure, determining its

cause, and recommending a solution. A

company can select its own engineer, an

outside consultant, or both. If a consultant

is called in, this should be done as

early in the process as possible.

Though similar procedures apply to

any failure analysis, the specific approach

can vary depending on when and

where the inspection is made, the nature

of the failure, and time constraints.

Contact fatigue. In another failure

mode, called contact or Hertzian fatigue,

repeated stresses cause surface cracks

and detachment of metal fragments from

the tooth contact surface, Figure 1. The

most common types of surface fatigue are

macropitting (visible to the naked eye)

and micropitting.

Macropitting occurs when fatigue

cracks start either at or below the surface.

As the cracks grow, they cause a

piece of surface material to break out,

forming a pit with sharp edges.

Based on the type of damage, macropitting

is categorized as nonprogressive,

progressive, spall, or flake. The nonprogressive

type consists of pits less than 1

mm diam in localized areas. These pits

distribute load more evenly by removing

high points on the surface, after which

pitting stops.

Progressive macropitting consists of

pits larger than 1 mm diam that cover a

significant portion of the tooth surface. In one type, called spalling, the pits coalesce

and form irregular craters over a

large area.

In flake macropitting, thin flakes of

material break out and form triangular

pits that are relatively shallow, but large

in area.

Micropitting has a frosted, matte, or

gray stained appearance. Under magnification,

the surface is shown to be covered

by very fine pits (less than 20

mm deep).

Metallurgical sections through these pits

show fatigue cracks that may extend

deeper than the pits.

Reference: Not shown in this demonstration version.