Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Grinding cracks caused by failure to temper a part - Machining defects - Fractography

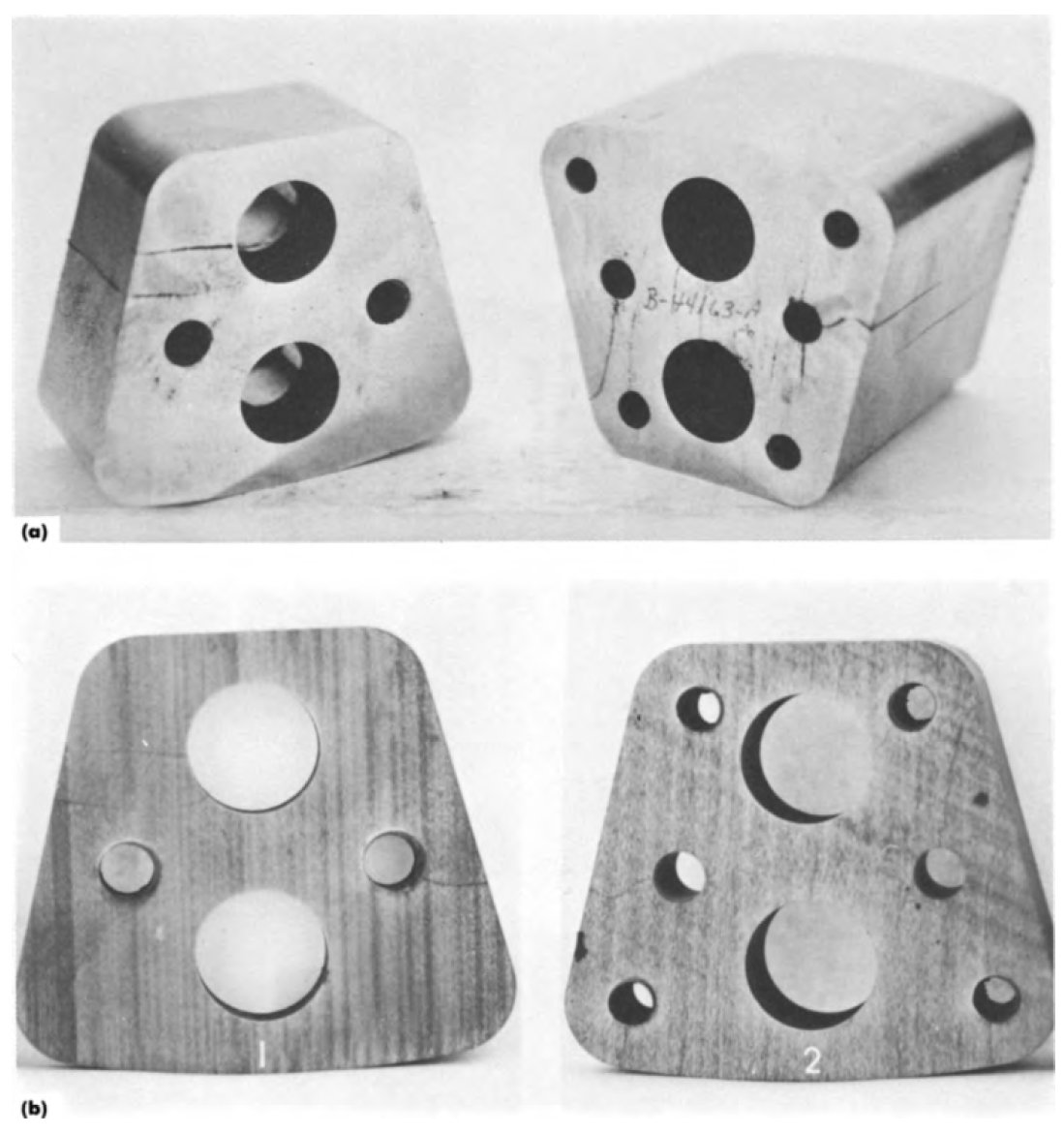

Figure 1: (a) Two dies made from AISI D2 tool steel that cracked after finish grinding (cracks accentuated with magnetic

particles), (b) Macroetching (10% aqueous nitric acid) of the end faces revealed grinding scorch. These dies were

not tempered after hardening.

Defect name: Grinding cracks

Record No.: 2329

Type of defect (Internal/Surface): Surface

Defect classification: Machining defects, fractography

Steel name: AISI D2 tool steel

Steel composition in weight %: No data.

Note: Failures due to finish grinding. Cracking

due to the stresses and microstructural

alterations caused by grinding is a relatively

common problem. In many cases, the grinding

technique is not at fault, because the

microstructure of the part rendered it sensitive

to grinding damage due to failure to temper

the part or because the part was overaustenitized

and contained substantial unstable retained

austenite.

Figure 10 shows an example of grinding

cracks due to failure to temper the part. Two

AISI D2 tool steel dies, which measured

57 x 60 x 29 mm or 51 mm thick

(2'A x 23/8 x l'/8 in. or 2 in. thick), were

observed to be cracked after finish grinding.

The cracks are emphasized with magnetic particles.

Macroetching of the surfaces revealed

the classic scorch pattern indicative of abusive grinding. The failure, however, was not due to

poor grinding practice, but was caused by

failure to temper the dies. The interior hardness

was 63 to 64 HRC, typical for as-quenched D2.

The scorched surface was back tempered to 55

to 58 HRC. It is difficult to grind as-quenched

high-hardness tool steels without damaging the

surface.

Reference: Not shown in this demonstration version.