Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Hot top cavity - ESR ingot defects

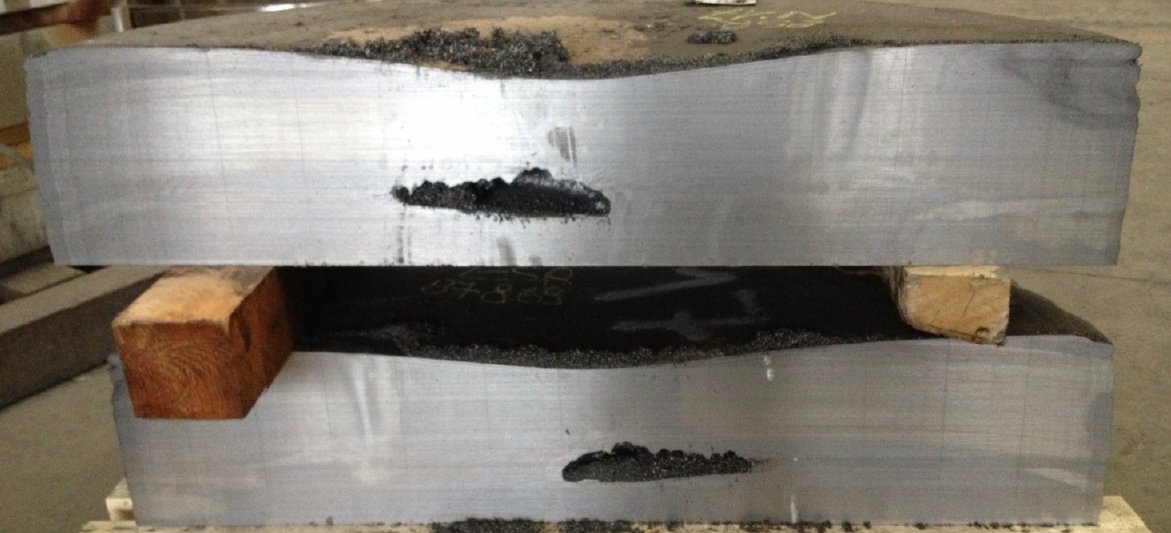

Figure 1: Example of hot top cavites.

Figure 2: Example of hot top cavites.

Defect name: Hot top cavity

Record No.: 2423

Type of defect (Internal/Surface): Internal

Defect classification: ESR ingot defects

Steel name: Steel

Steel composition in weight %: No data.

Note: ESR is known as an alternative step on the continuous improvement in single ingot

production for heavy forgings. In the recent past a new state of the art ESR remelting system was

installed with the possibility to produce ingots in diameter from 1000 mm for 45 tons till 2000 mm

for 145 tons. Consumable electrodes from traditional fabrication processes which consist of melting

with electrical arc furnace, refining, degassing of the steel and bottom pouring will be used to

produce one single heavy ingot with best cleanness with the help of electrode exchange technique.

This paper tells about the furnace characteristics and the efforts to be made to ensure high quality

level in material and furnace preparation as well as save automatic production performances during

remelting and electrode exchange. Finally the results of ingots characterized by an elevated level of

chemical homogeneity and internal quality such as to ensure the absence of defect greater than

0.5 mm AVG during the final inspection of the forged part from the ESR production will be

presented. The ESR process serves for the reproducible quality in heavy ingot making and tightens

the limits in specifications together with high material yield.

Consequences of our inexperience were evident in a marked undulation of the skin, in a too limited

cap of slag at the end of remelting, in an evident ring in correspondence with the electrode change.

All this points do not represent big problems themselves but they have to be read as external

evidence of bigger possible internal problems: for examples, a small cap should immediately

suggest a possible shrink hole wider than desired and a too manifest electrode change position can

be easily linked to a non optimal internal structure of the ingot. At the end, the result of all the efforts done during remelting can be “measured” by the top and

bottom scrap percentage. While the lower part of the ingot should be discarded because of some

metallurgical reason related to the chemical composition variation and solidification direction

strongly influenced by the copper base plate, the upper part is affected by porosity and shrink hole

cavity strictly connected to how good is the hot top part of the melting profile (figs. 1 and 2) : better you

are able to manage the closing of the process, more material you can save on your ingot.

Unfortunately, this is absolutely not easy to obtain, in fact the hot top part of the recipe is the most

difficult part to optimize during remelting and often it required more than one cast to obtain a

satisfactory result.

Reference: Not shown in this demonstration version.