Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Failure of a long I-beam. - Fractography - Rail defects

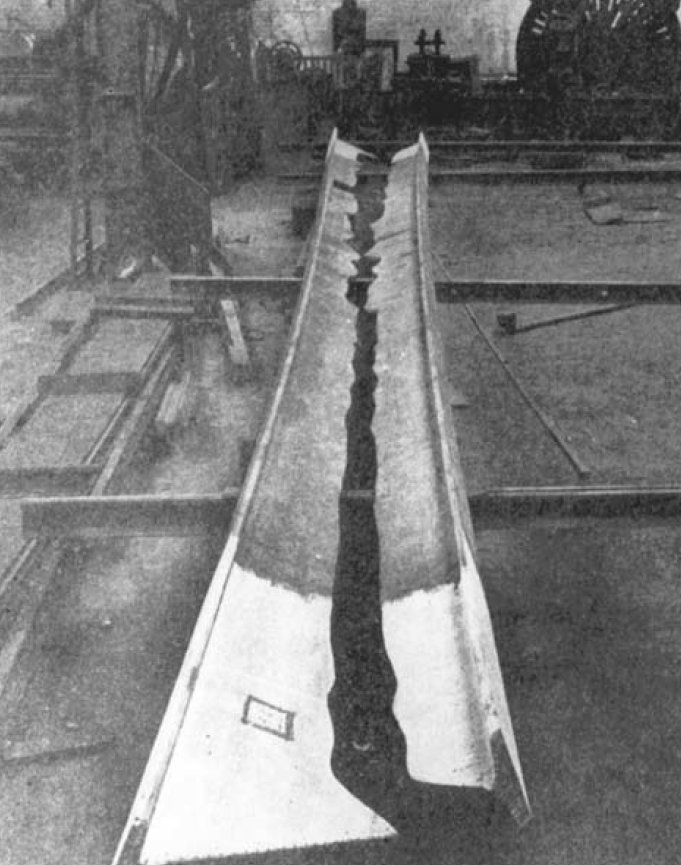

Figure 1: 12 m long I-beam split along the web. With kind

permission of Reinhold Publishing Company.

Defect name: No data.

Record No.: 2948

Type of defect (Internal/Surface): Surface

Defect classification: Fractography, rail defects

Steel name: Steel

Steel composition in weight %: No data.

Note: When components are manufactured from metals and alloys by

the various operations, an important parameter that is overlooked

is the residual stress retained during fabrication. Unless adequate

precautions are taken to reduce or eliminate them, residual stresses

can lead to unexpected failures. This is illustrated by an incident

in Belgium in 1934. A 12 m long I-beam of high-strength steel

fractured suddenly while lying flat on the shop floor, with an explosive

noise. Figure 1 shows the beam, which had

split along the entire length of the web. Both halves had curved

with an outside concavity of the flanges, with deflections up to 8

cm. On the day before, skew cuts had been made at its two ends

with a torch. The spontaneous fracture was attributed to the state

of stresses introduced during the hot rolling of the beam. The web cooled faster than the flanges. The contraction of the flanges by

cooling was prevented by the web, which induced high stresses in

the beam. This state of precarious internal equilibrium was disturbed

by the flame cutting. It is believed that under the heavy

state of residual stresses, flame cutting followed by cooling produces

a kind of artificial strain aging and hardening locally and

generates cracks. These cracks must have grown slowly, until

reaching the critical length.

A somewhat similar beam failure was reported at the Indira

Gandhi Centre for Atomic Research, Kalpakkam, the crack in this

case following a path along which there was excessive sulfur segregation.

Reference: Not shown in this demonstration version.