Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Carbon segregation map - 3.3 t ingot - Ingot defects

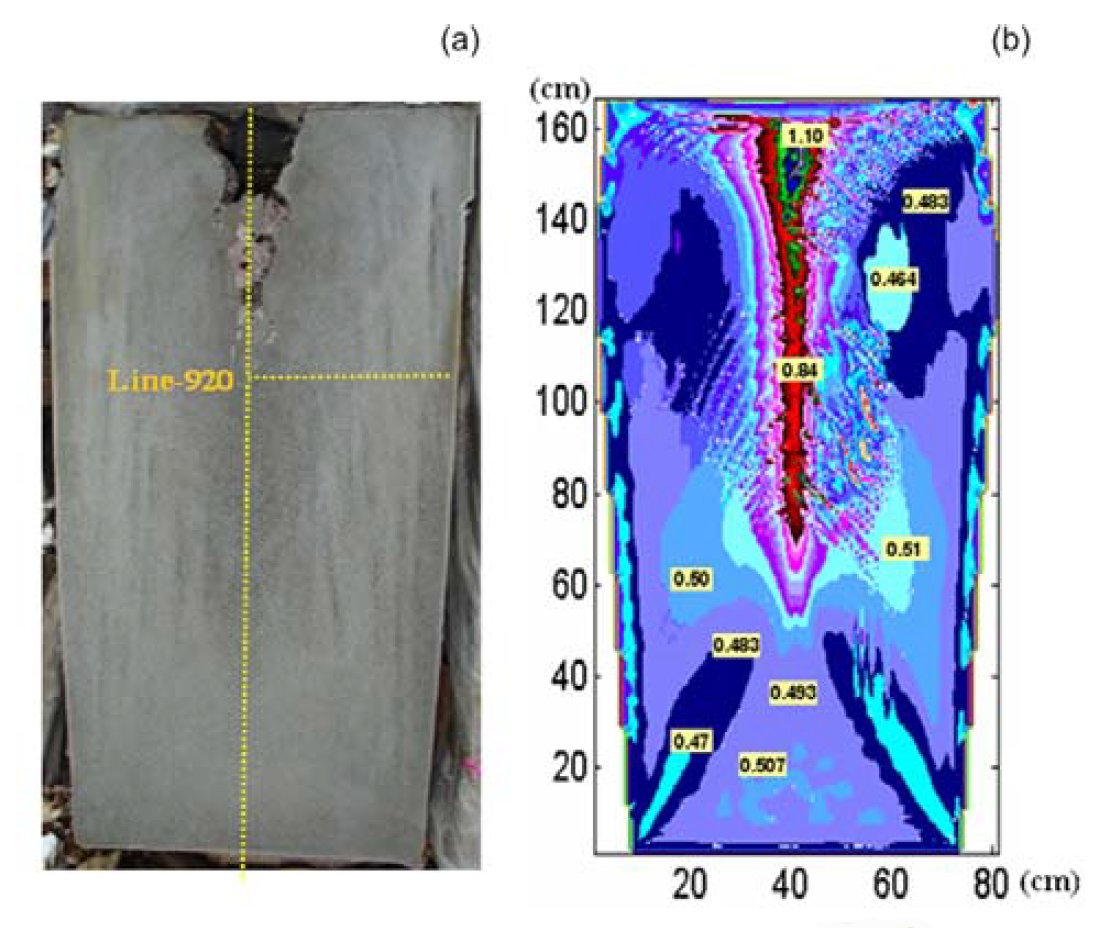

Figure 1: Carbon segregation map: (a) sulfur-print of the

experimental ingot, (b) simulation result.

Defect name: Segregation

Record No.: 3358

Type of defect (Internal/Surface): Internal

Defect classification: Ingot defects

Steel name: Steel

Steel composition in weight %: 0.49% C, 0.23% Si, 0.51% Mn, 0.03% P, 0.03% S.

Note: Comparison between the sulfurprint

of the experimental ingot and numerical prediction

is shown in Fig. 1. For the sulfur-print, dark color

corresponds to positive segregation, and light color

corresponds to negative segregation. Some black discontinuous

lines, close to the ingot surfaces, are called

A-segregates in which the solute is enriched. We can

note that the general segregation pattern in the experiment

is well reproduced in the simulation, such as

top positive segregation, bottom negative segregation,

and A-segregates.

Reference: Not shown in this demonstration version.