Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Alligatoring - 9Cr-1Mo steel - Rolling defects

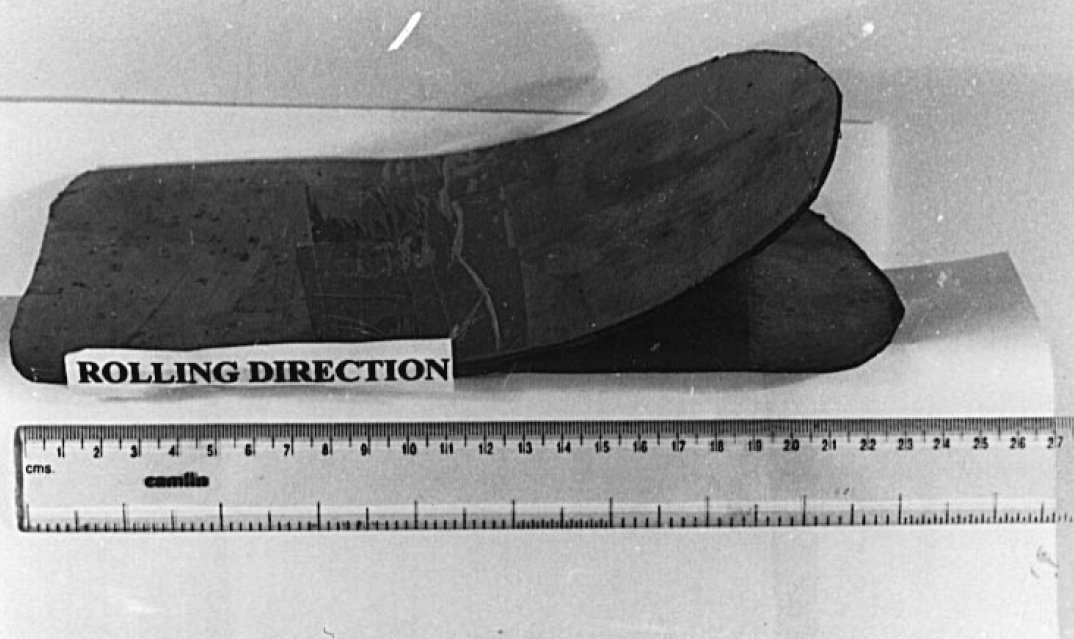

Figure 1: Failure of AR material by alligatoring after about 40% reduction at room temperature rolling.

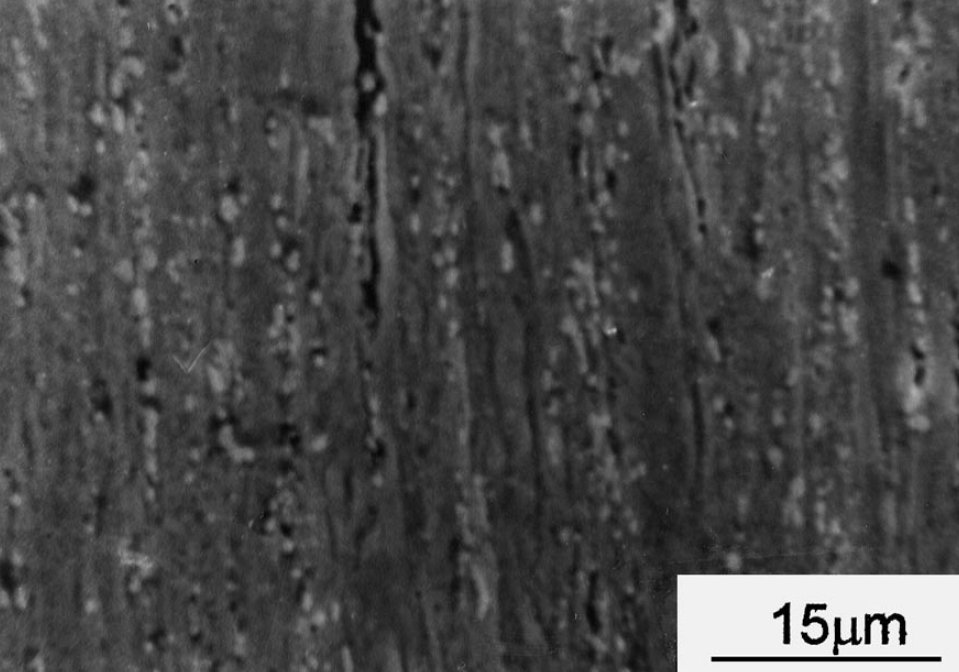

Figure 2: Micrograph showing cracks associated with carbides.

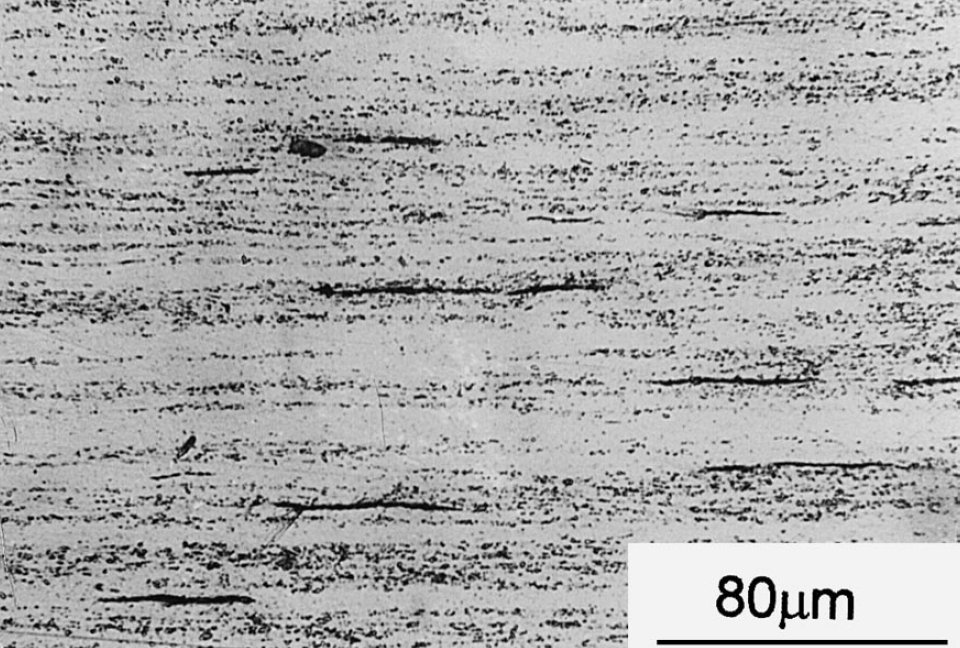

Figure 3: Multiple cracks at planes away from centre in the sheet

failed by alligatoring. These cracks remain stable and do not

take part in final failure.

Defect name: Alligatoring

Record No.: 676

Type of defect (Internal/Surface): Internal

Defect classification: Rolling defects

Steel name: 9Cr-1Mo tool steel

Steel composition in weight %: 0.10% C, 0.35% Mn, 0.50% Si, <0.025% P, <0.025% S, 9.50% Cr, 1.00% Mo, 0.08% Nb, 0.21% V, 350 ppm N.

Note: Alligatoring damage was encountered during the rolling of a modified 9Cr-1Mo steel in the as-received condition.

The cause of this failure was attributed to the banded nature of the microstructure formed by coarse carbides, which

aids the nucleation of the voids at the interface. The banded microstructure was destroyed by a heat treatment which

gives a uniform fine distribution of carbides. Such a microstructure could eliminate the alligatoring problem in this

steel.

The modified 9Cr-1Mo steel was received as a hot rolled billet with square cross section of 120x120 and 240 mm long, the chemical composition for which is given in the upper text.

The AR plates were rolled in a two high mill (roll

diameter=190 mm) at room temperature such that the

rolling direction parallel to the transverse direction.

Cold rolling was done under heavy lubrication (using

lubricating oil) in order to minimise the friction, which is

suspected to be possible cause of alligatoring. The

rolls were greased after each pass. The plates started

failing by alligtoring after a reduction in thickness of

about 30%-40% during room temperature rolling (with

a reduction 5pct/pass) (Fig. 1). Rolling of rods (~25

mm in diameter) cut along the transverse direction of the

billet were also attempted and the material also failed by

alligatoring. The 710T plates were rolled under exactly

similar conditions at room temperature and the plates

could be rolled from a thickness of 20 to 2 mm without

alligatoring defect.

The phenomenon of alligatoring in this steel can be

attributed to the presence of carbides lying as bands parallel to the sheet rolling direction. The carbides in

the centre plane of the plate are under tensile loading

during the initial stages of rolling and the voids

nucleate at the carbide-matrix interface. The voids

subsequently join up to form small cracks. As more

voids accumulate, the crack extends in length, in the

direction of rolling, with increasing strain (Fig. 1). The

stresses in the plate are expected to reverse as the

plates become thin. This should cause tensile

stresses away from the centre plane and the cracks

should form in these planes as well at the carbide±

matrix interface. Fig. 3 shows stable cracks in the

planes away from the centre plane. The cracks are not

expected to `heal' in the course of rolling because of

the carbide particles within them. The final failure is

further assisted by the concavity developed at the front

end of the sheet which can act as stress riser. This

acts as the initiation site for the alligatoring failure.

The normal stresses that exist at the front end of the

plate at the exit from the rolls, is sufficient to spilt the

slab along the centre plane, which is already weakened

by small cracks. Thus the failure is invariably along the

centre plane of the sheet even if cracks are present in

other planes as well.

Reference: Not shown in this demonstration version.