Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

New Records

Surface Defects

Contact Us

Help

Home

Defects in Steel Products

Defects in steel products are defined as deviations in appearance, shape, dimension, macro-structure/micro-structure, and/or chemical properties when compared with the specifications given in the technical standards or any other normative documents in force. Defects are detected either through visual inspection or with the help of instruments

and equipments.

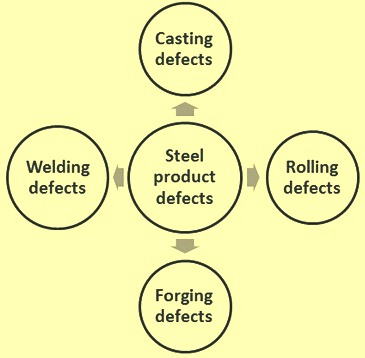

There are four main metallurgical processes for the manufacture of finished steel products where the steel products can pick up defects. The defects picked up during these processes are (i) casting defects, (ii) rolling defects, (iii) forging defects, and (iv) welding defects. (Fig 1).

Figure 1: Metallurgical processes and steel product defects.

Reference: Website http://ispatguru.com/metallurgical-processes-and-defects-in-steel-products, 2017.