Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Carpenter specialty alloys

Material Name: Carpenter specialty alloys

Recipe No.: 12062

Primary Chemical Element in Material: Fe, Ni

Sample Type: Bulk

Uses: General microstructure

Etchant Name: No data

Type (Macro/Micro): Micro

Etching Method: Chemical, electrolytic

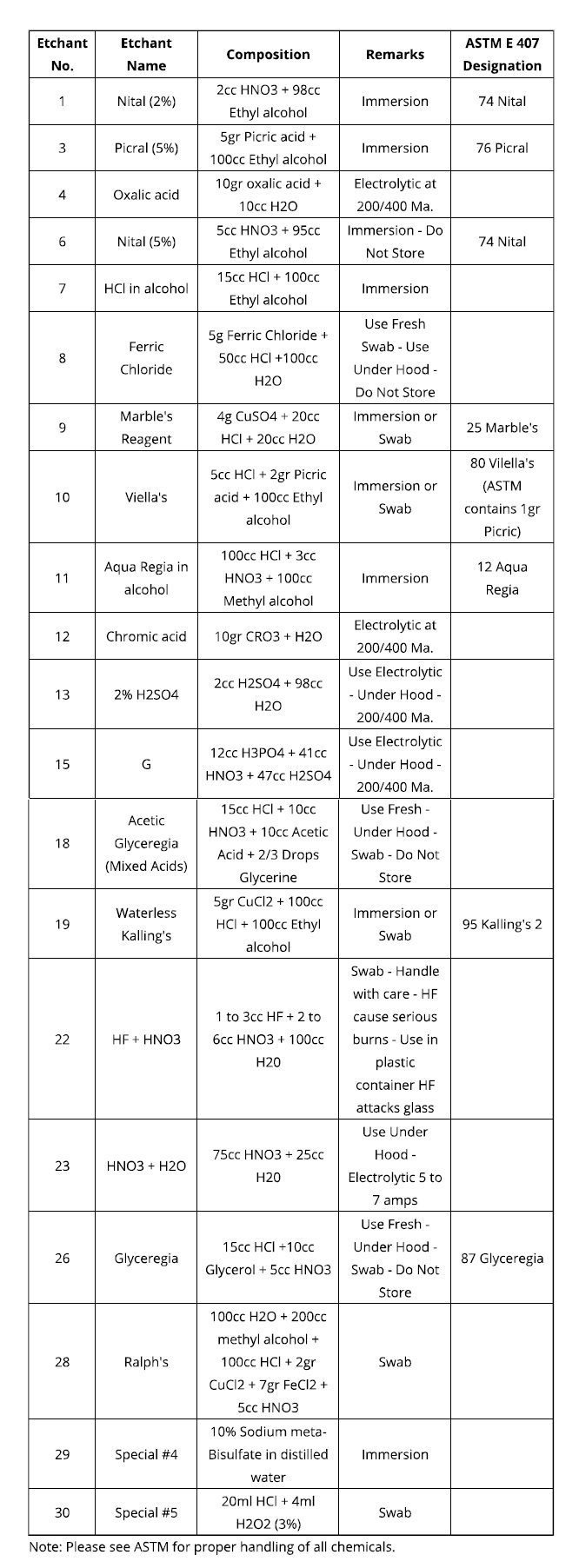

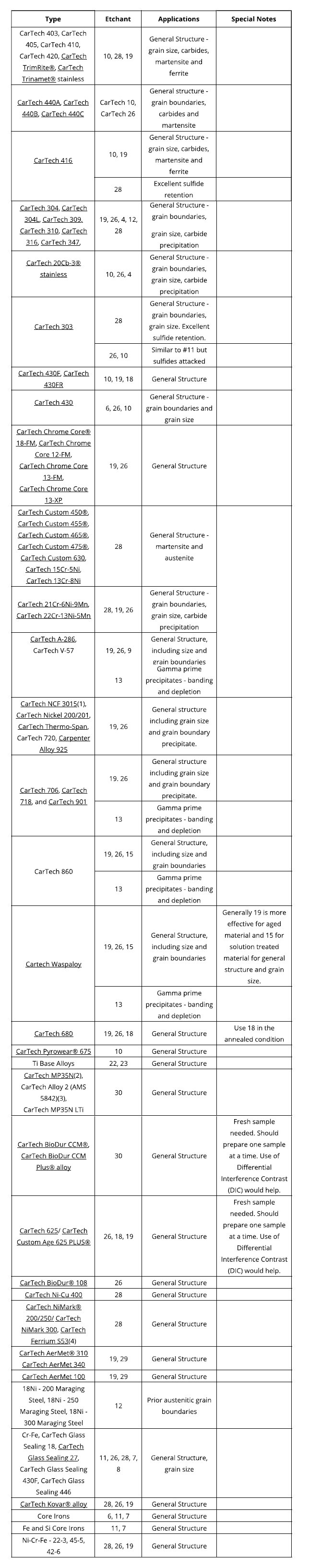

Etchant (Electrolyte) Composition: See the tables 1 and 2.

Procedure (Condition): See the tables 1 and 2.

Note: Light microscopy to evaluate the microstructure of metals is employed extensively by quality control and failure analysis laboratories. Selection of the proper etchant depends largely upon alloy composition, heat treatment and processing. The etchants used in metallographic examination are solutions of acid and chemicals and are applied selectively to attack a highly polished surface, thus permitting microstructural examination.

There are three basic methods of etching alloy samples – immersion, swabbing and electrolytic. In the first method, the sample is immersed in the etching solution until the desired structure is developed. Samples may be immersed in stain etchants to highlight specific microstructural features.

In the second, the sample is swabbed with cotton that has been immersed in the etchant. In electrolytic etching, a D.C. source or a rectifier serves as the power supply, and the specimen is the anode in the electrolytic cell. Power requirements can be adjusted as needed, depending on sample size, anode-to-cathode spacing, electrolyte, etc.

The following rules should be observed to obtain a true and representative microstructure:

1. If a mounted specimen is used, an adherent mount is very important. Separation between the specimen and the mounting compound can result in “bleeding” of the residual etchant or water, and subsequent staining.

2. A good metallographic polish is a must. The sample must be free of scratches, disturbed metal and any kind of embedded contaminants.

3. The specimen must be thoroughly cleaned before etching. Oil or any polishing compounds must be removed.

4. After etching, the sample should be rinsed in HOT water, followed by an alcohol rinse and dried under HOT air. (Note: an alcohol rinse can dull/wash out a stain etch.) Samples with cracks must be thoroughly dried to prevent bleeding.

5. If additional etching time is required, the specimen should be re-rubbed a few seconds.

on a final polishing wheel. If this is not done, “flashing” can occur in certain alloys, necessitating a complete re-polish. Flashing will not occur and re-rubbing is not required if the alloy being etched forms no passive oxide layer, or if etching is performed electrolytically (rerubbing is usually mandatory only when using Ralph’s, Glyceregia, Acetic Glyceregia and HCL + H2O2 etchants). More complete specimen preparation instructions are readily available in literature.

Reference: Website Carpenter Technology, https://www.carpentertechnology.com/en/alloy-techzone/technical-information/manufacturing-guides/a-guide-to-etching-specialty-alloys-for-microstructural-evaluation, 2019.

Table 1: List of etchants.

Click the table to enlarge the data.

Table 2: List of alloys.

Click the table to enlarge the data.