Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Comet Tails

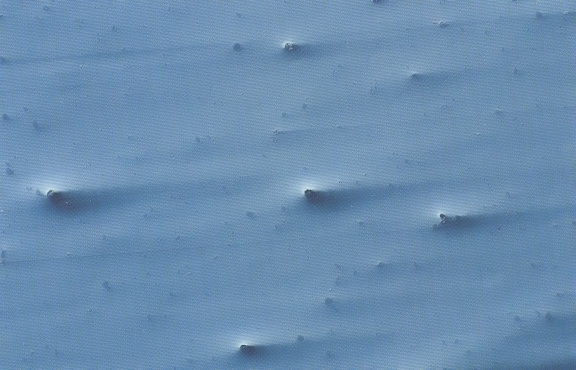

Example: Comet tails, Mag. 200x, DIC.

Comet tails accur adjacent to inclusion or pores, when the motion

between sample and polishing disc is undirectional. Their charcteristic

shape earns the name "comet tails". A key factor in avoiding comet tails

is the polishing dynamics. There are many variables in the metalographic

polishing process. The most commonly recognized are items such as cloth

and abrasives. While these gave a great effect on the polishing process,

other critical parameters are often neglected. These parameters are the

polishing dynamicss. The dynamics or speed of the sspecimen in relation

to the cloth plays an important role in the final otcome of the polishing

process. Artifacts such as commt tails, pull-outs, and edge rounding can

be attributed to an imbalance in the dynamics.

Reference: Metalog Guide, page 86-87,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.